Ensure Quality Checks at Every Process

Implement thorough and automated quality checks at every stage, from raw materials to finished goods, ensuring product consistency and compliance.

Manufacturers Love ManufApp

Trusted by manufacturers to drive digital transformation.

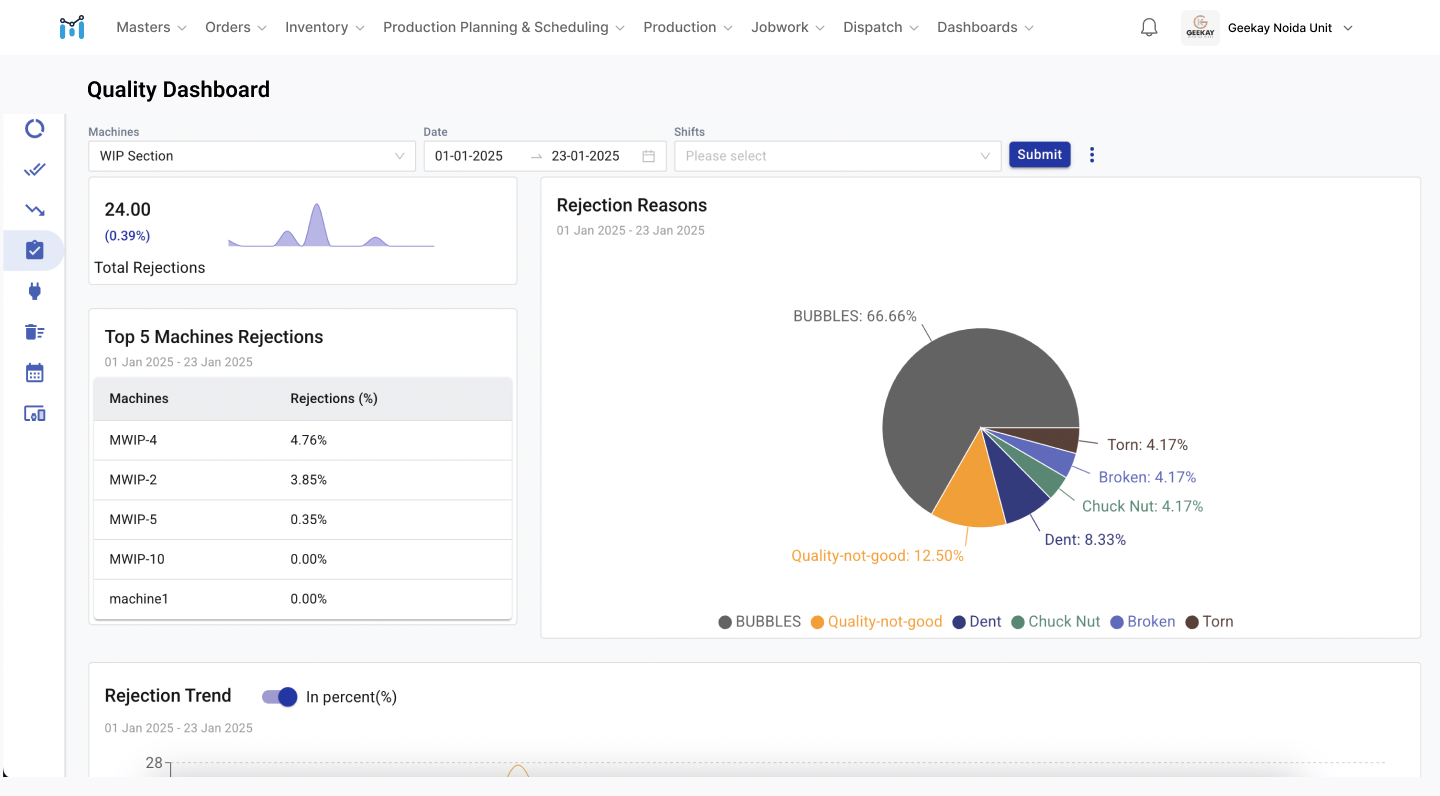

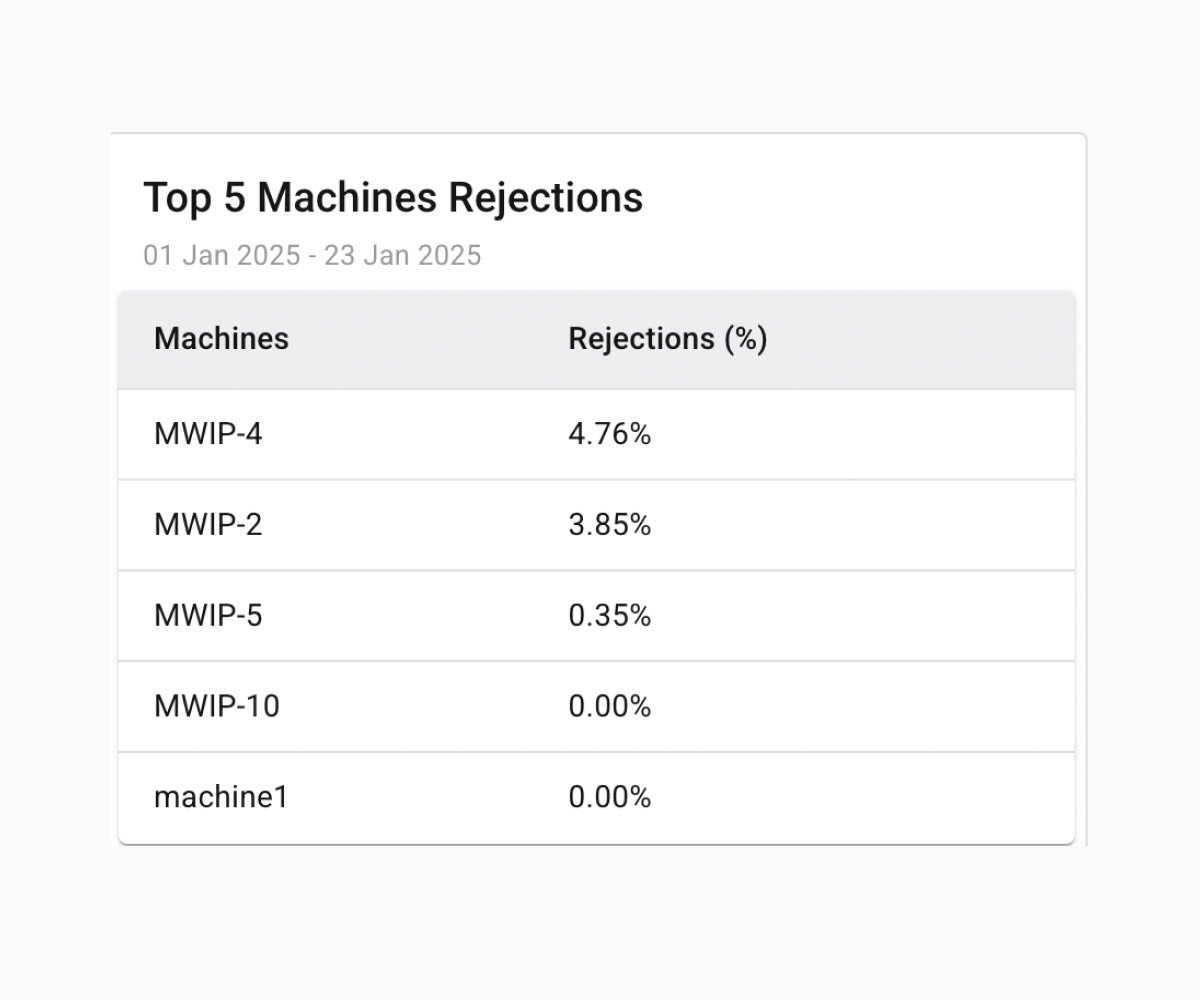

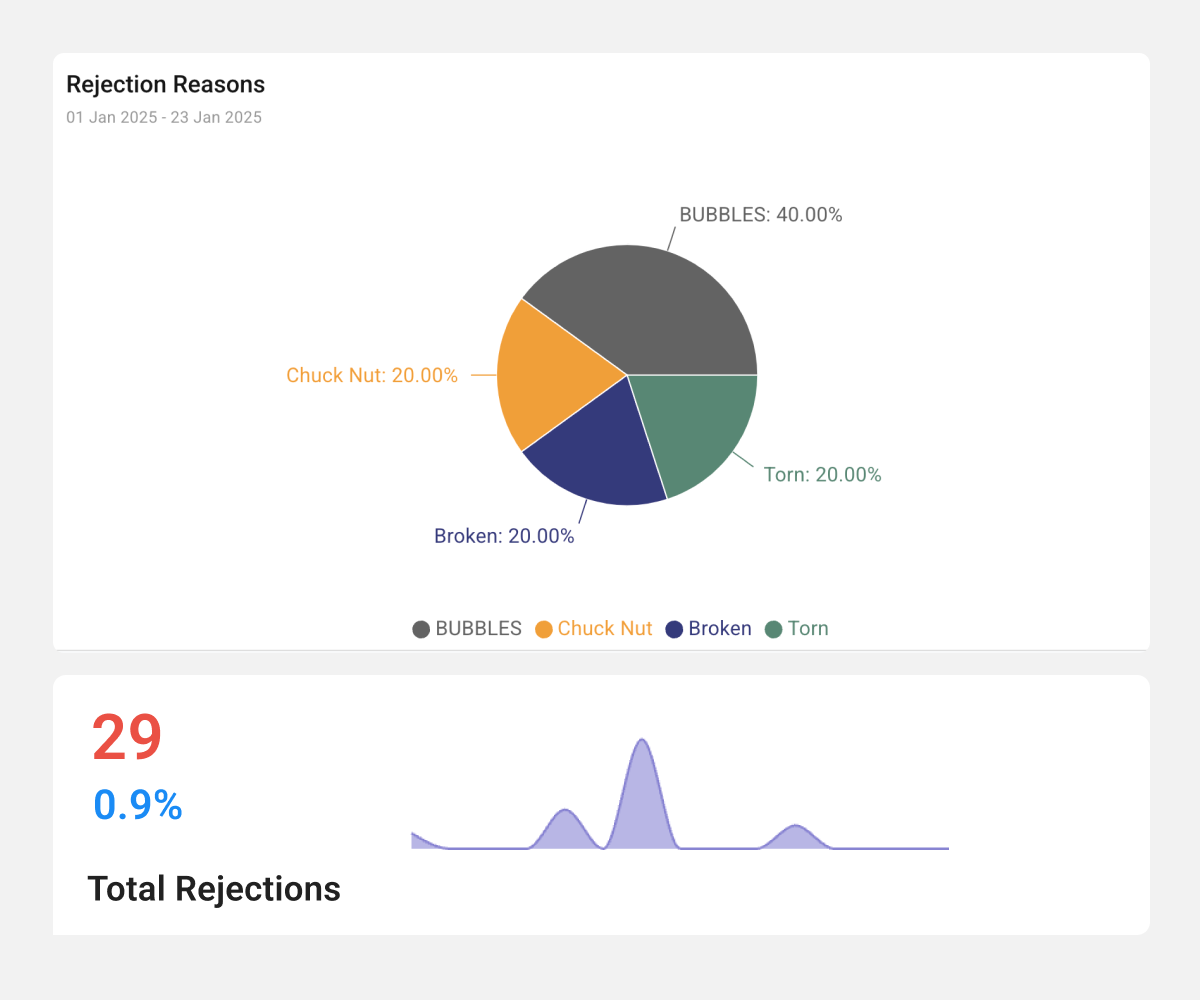

Department-Wise Analysis for Targeted Quality Improvements

Gain insights into each department’s performance with detailed analysis, allowing you to address specific quality issues and improve efficiency across the board.

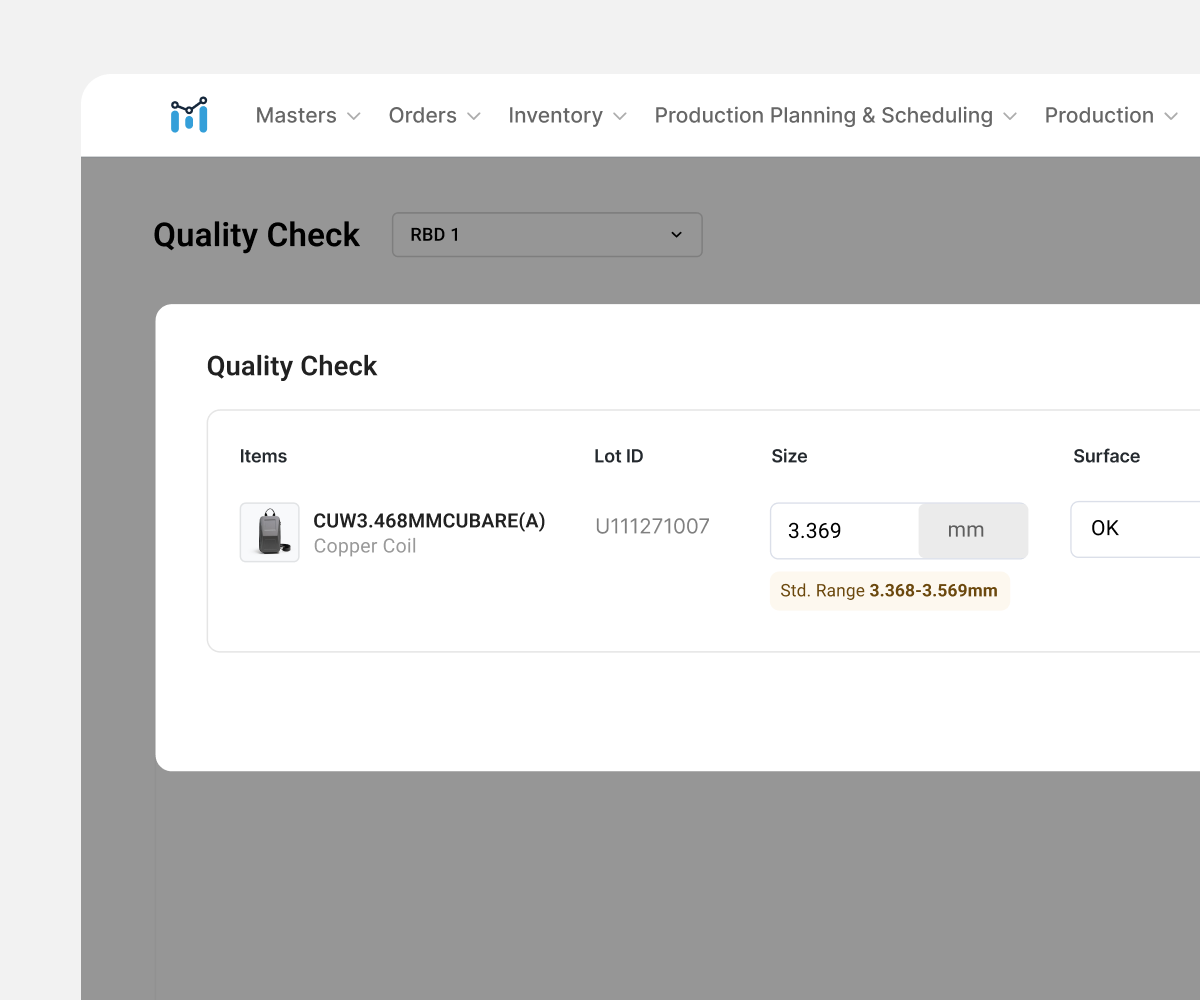

Comprehensive Inward & In-Process QC for Consistent Standards

Ensure that quality standards are maintained throughout production by performing real-time quality checks during both the inward inspection and in-process stages.

Monitor Critical to Quality Parameters for Flawless Production

Track and optimize critical quality parameters to ensure that every product meets your exacting standards, reducing defects and enhancing product consistency.

Detailed Quality Reports for Informed Decision Making

Generate comprehensive, real-time quality reports that provide actionable insights, helping you make data-driven decisions and continuously improve production quality.

Quality in industrial organizations is important in meeting customer requests as well as statutory requirements.

The quality and inspection section of Manufapp provides industries with quality control measures throughout the manufacture of high-quality products.

Why Quality and Inspection Are Important:

Quality management benefits manufacturers as follows:

- Maintain Consistency: Reduce the incidence of defects and variations in products.

- Ensure Compliance: Conform to regulations and follow applicable industry standards.

- Increase Customer Satisfaction: Deliver goods of such quality as meet the expectations of the customers.

Here Are the Key Features of the Quality and Inspection Module of Manufapp:

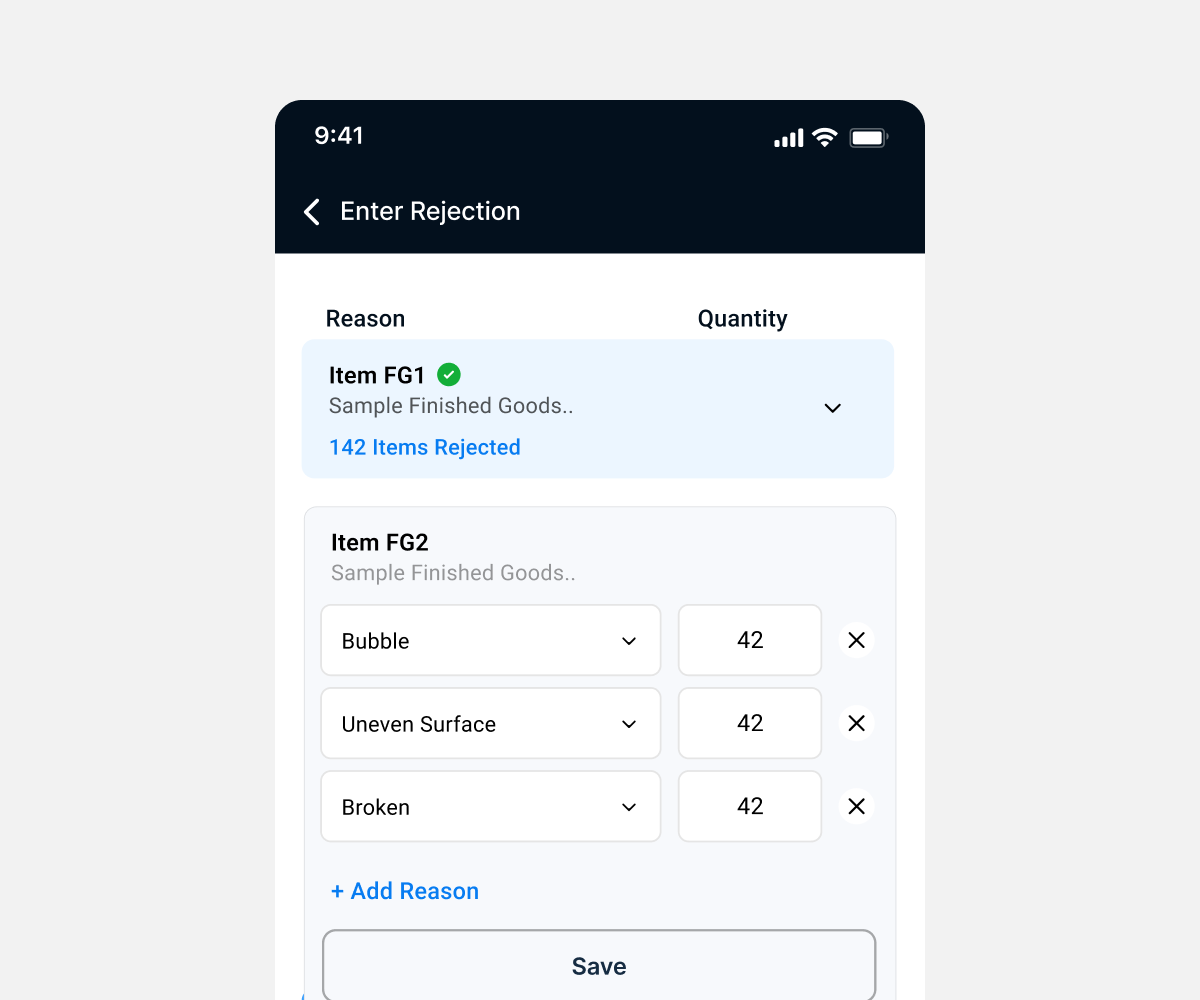

- Real-time Quality Inspection: Check products during different phases of manufacture, ensuring continuity of quality monitoring.

- Automated Reporting: Quality-related data are tracked, and compliance reports are generated.

- Non-conformance Management: Report and take quick corrective action on quality issues to minimize their recurrence.

- Root Cause Analysis: Study and solve the defects that affect quality to ensure steady improvement in product quality.

Manufapp is a tool for ensuring high product quality, compliance with regulations, and customer satisfaction through efficiency.

Make Your Manufacturing Intelligent Now

Need tailored assistance with your Manufacturing needs? Our expert team is available to help

Contact information:

Email: [email protected]

Phone: +91 97171 15905