Optimize Tool Usage and Maximize Efficiency

Monitor tool usage patterns to ensure each tool is utilized effectively, reducing idle time and extending the lifespan of your equipment.

Manufacturers Love ManufApp

Trusted by manufacturers to drive digital transformation.

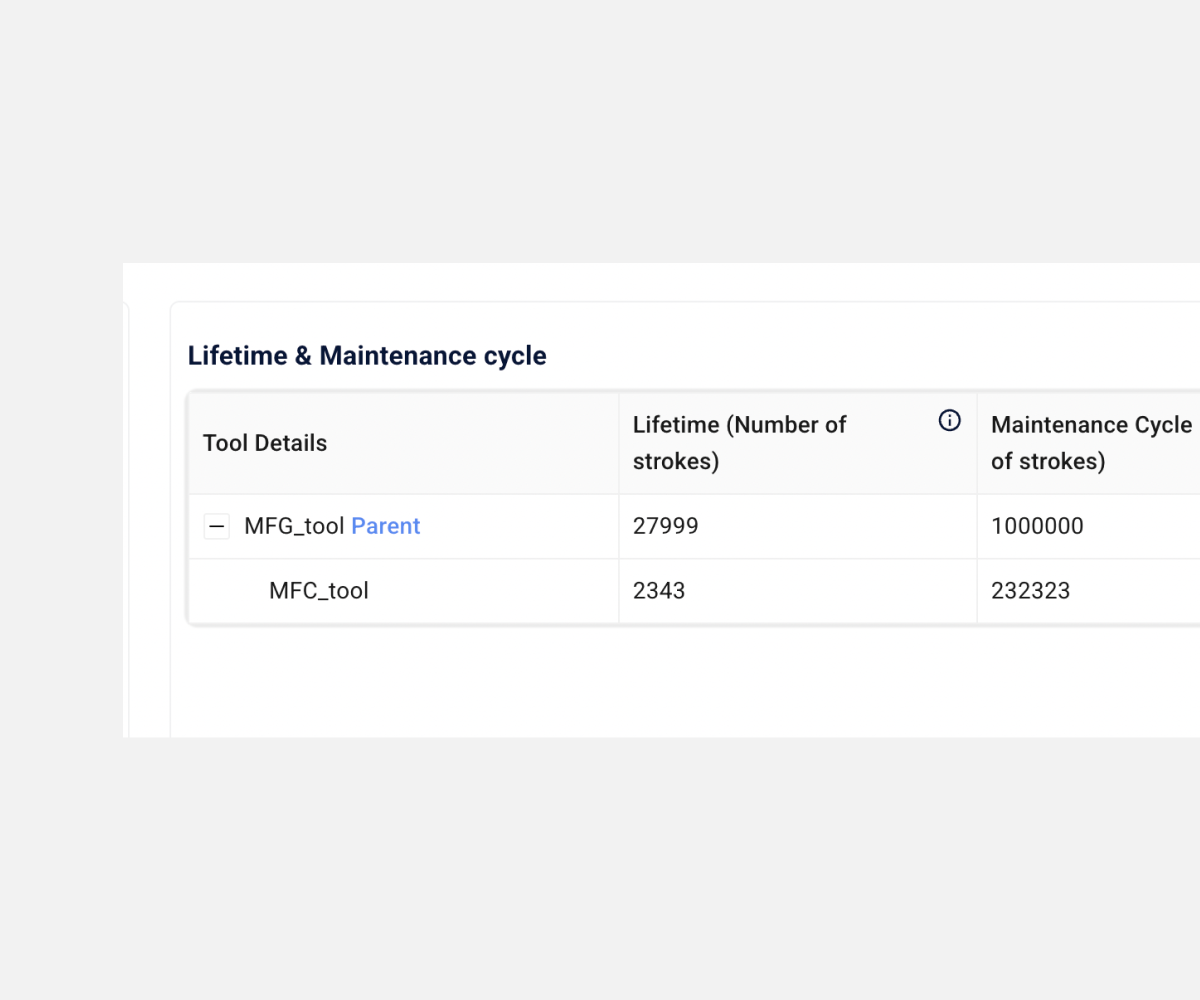

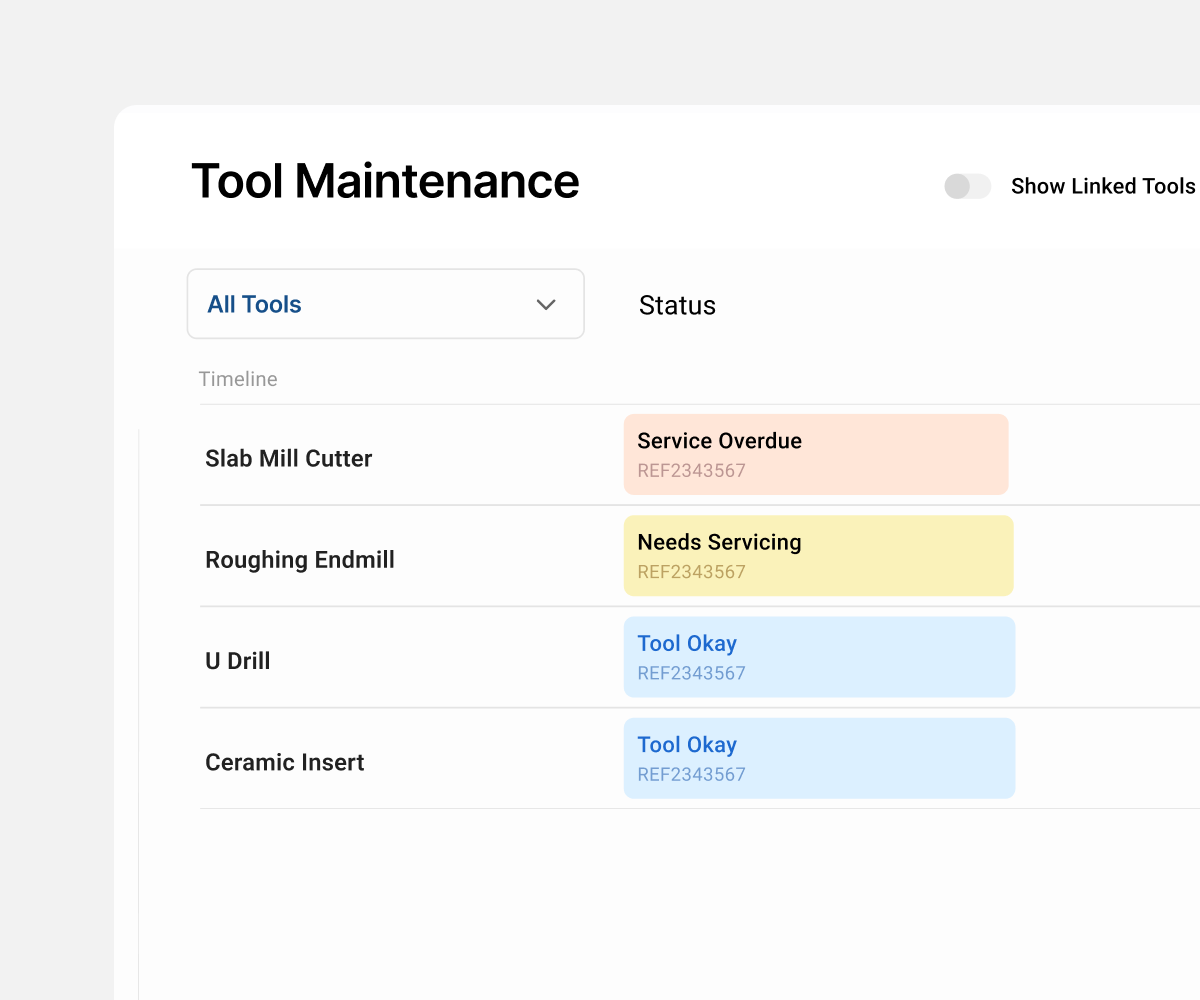

Track Tool Lifetime for Maximum Durability

Monitor the lifespan of each tool to ensure timely replacements or repairs, preventing unexpected breakdowns and reducing unplanned maintenance costs.

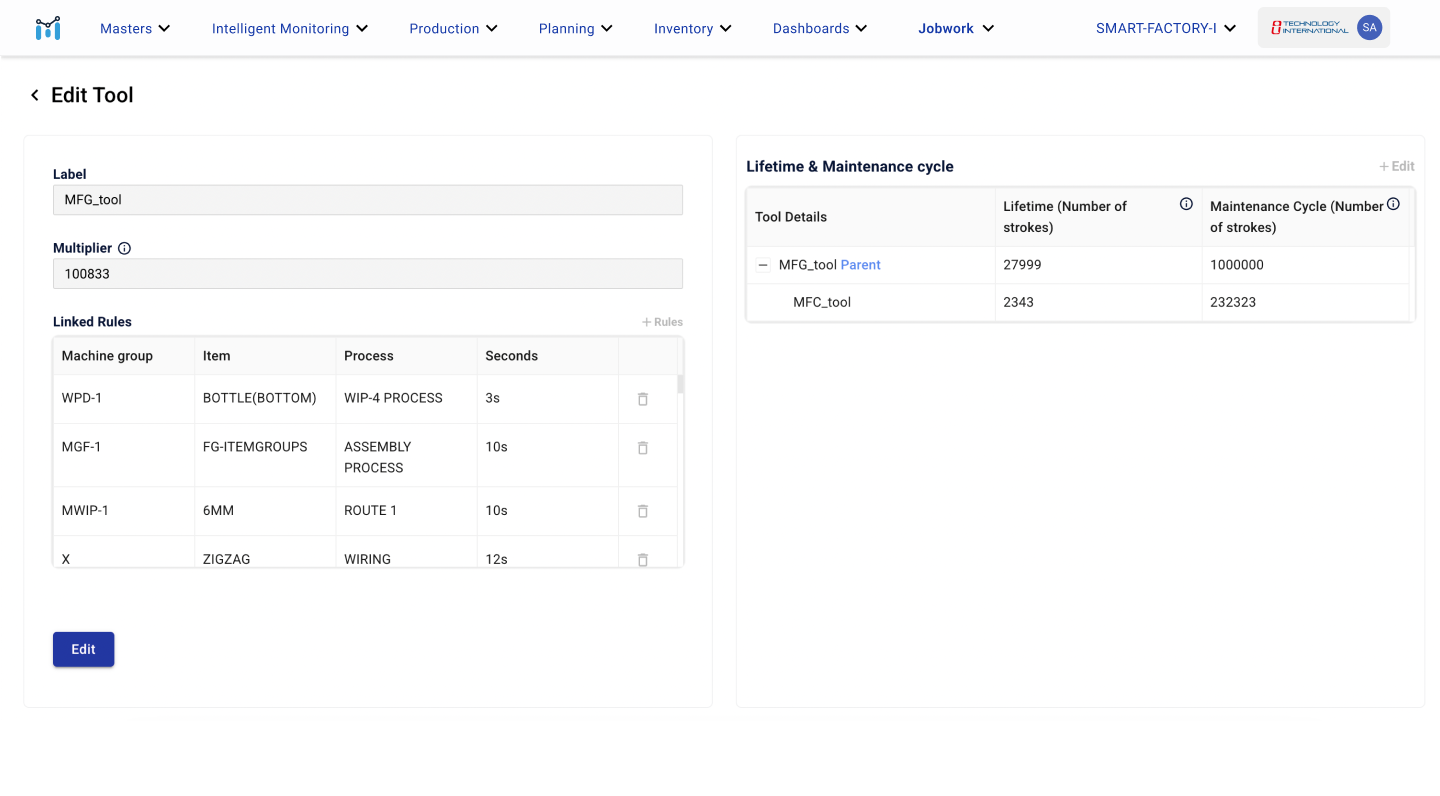

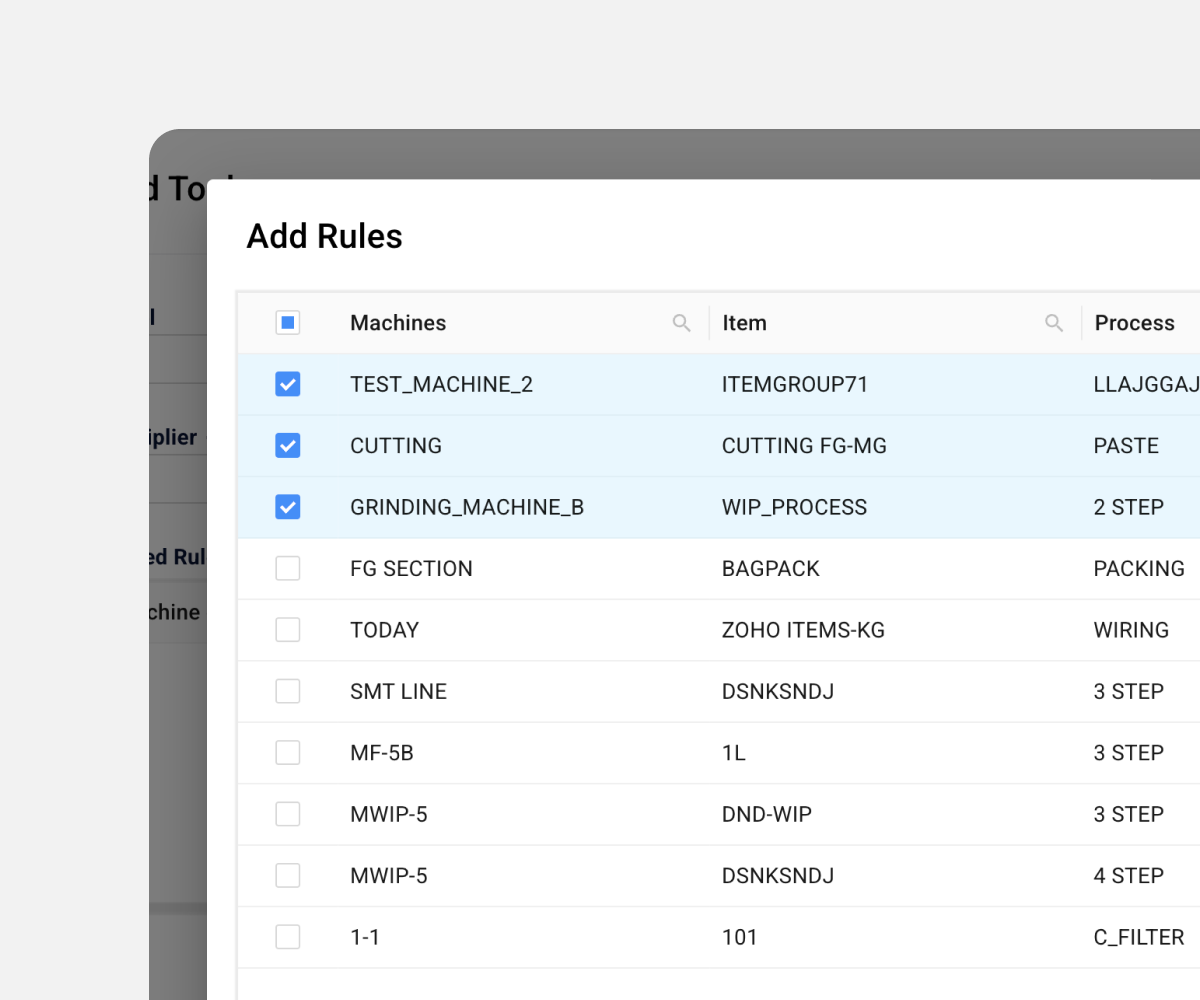

Efficient Tool Linkage for Seamless Integration

Link tools to specific work orders, machines, or operators, making it easy to track tool usage, assign them appropriately, and ensure they’re utilized effectively throughout the production process.

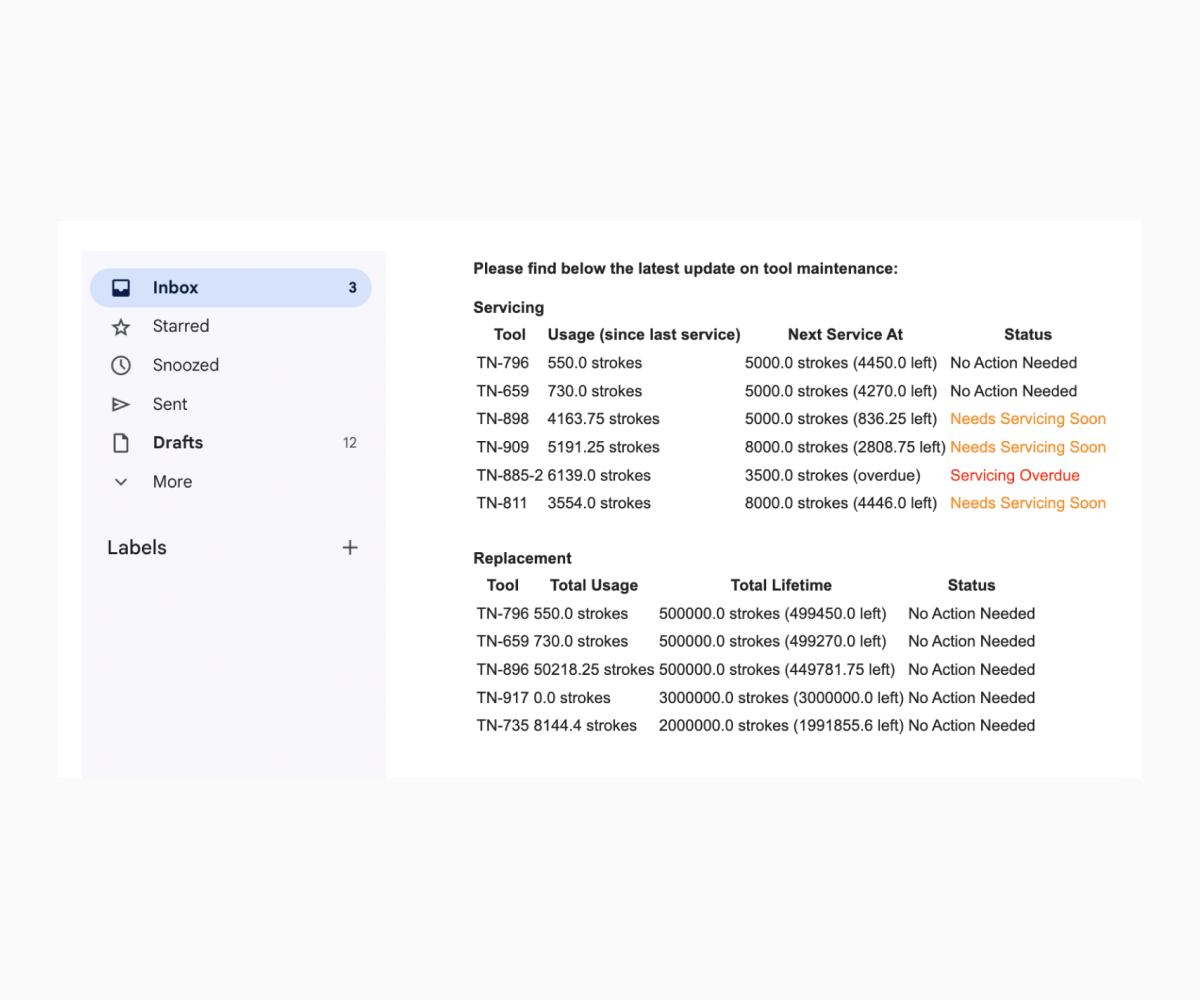

Stay Ahead with Automated Tool Alerts

Receive automated alerts for upcoming maintenance, replacements, or tool usage limits, keeping you ahead of potential issues and ensuring your tools are always ready for action.

Schedule Tool Maintenance Cycles for Optimized Performance

Automate maintenance scheduling based on usage data, ensuring tools are serviced regularly and kept in peak condition to avoid breakdowns and extend their life.

Tool Management

With effective tool management, production becomes seamless, allowing operations to run smoothly most of the time.

Manufapp’s Tool Tracking and Maintenance module manages tool tracking and maintenance to prevent breakdowns.

Why are Tools Managed?

- Lower Downtime: Proper tools can help to avoid production delays caused by misplaced or improper tools.

- Tool Longevity: Proper tracking and maintenance can extend a tool’s life.

- Savings: Lower costs for tool replacements and emergency repairs.

Key Features of Manufapp’s Tool Tracking and Maintenance Module:

- Tool Inventory Maintenance: Keep a complete and accurate record of existing tools.

- Preventive Maintenance: Schedule maintenance to avoid unexpected failures.

- Real-time Tool Tracking: Instantly identify and locate tools throughout the facility.

- Usage History Logs: Keep track of tool usage patterns to help you plan more effectively.

Manufapp’s tool management solution assists manufacturers in effectively utilizing tools, reducing waste, and increasing production efficiency.

Make Your Manufacturing Intelligent Now

Need tailored assistance with your Manufacturing needs? Our expert team is available to help

Contact information:

Email: sales@manufapp.com

Phone: +91 97171 15905