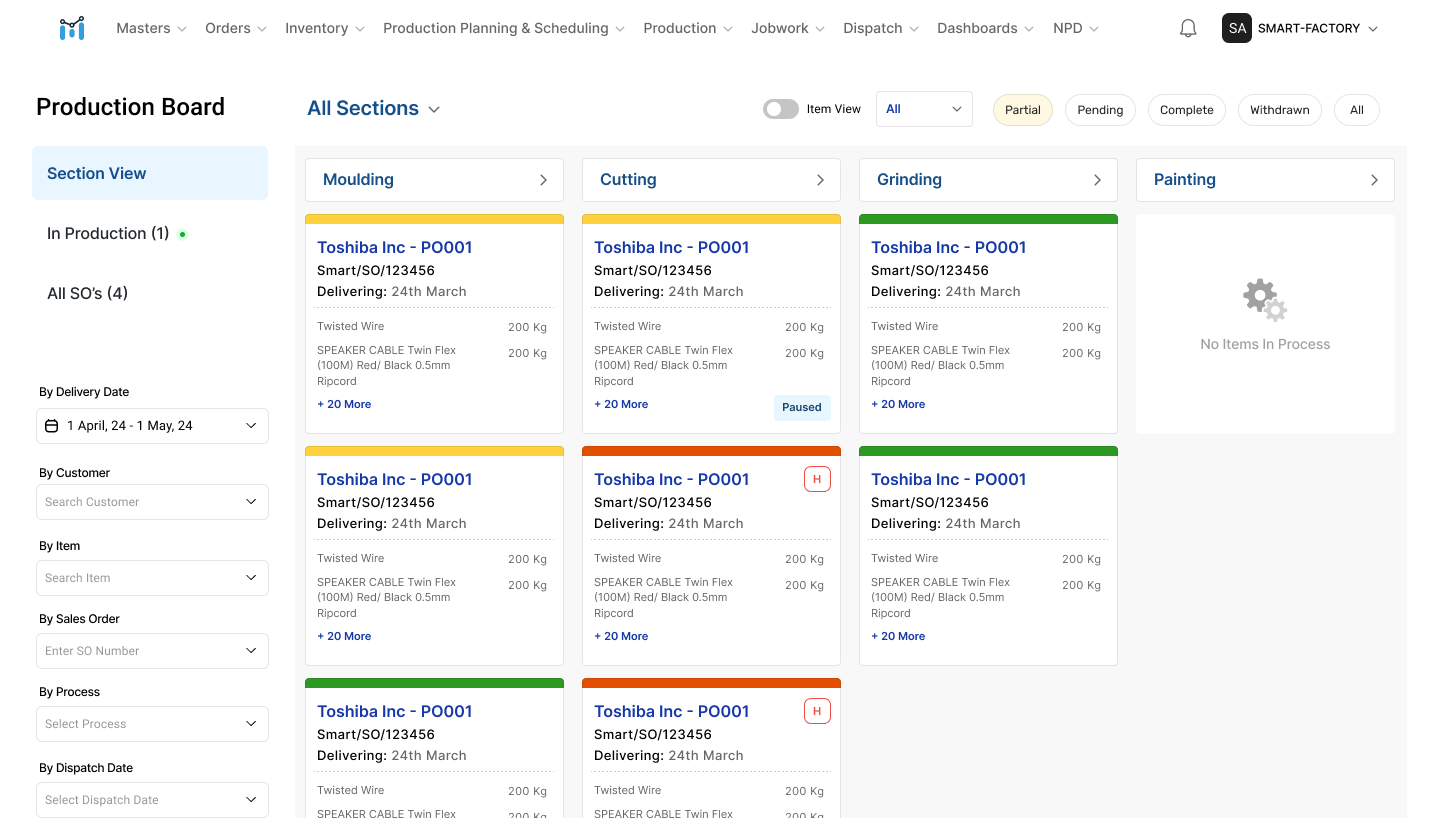

Monitor, Measure, and Manage: Redefining Production Excellence

Gain complete visibility into your production processes with real-time updates, actionable insights, and seamless control, ensuring efficiency and quality at every step.

Manufacturers Love ManufApp

Trusted by manufacturers to drive digital transformation.

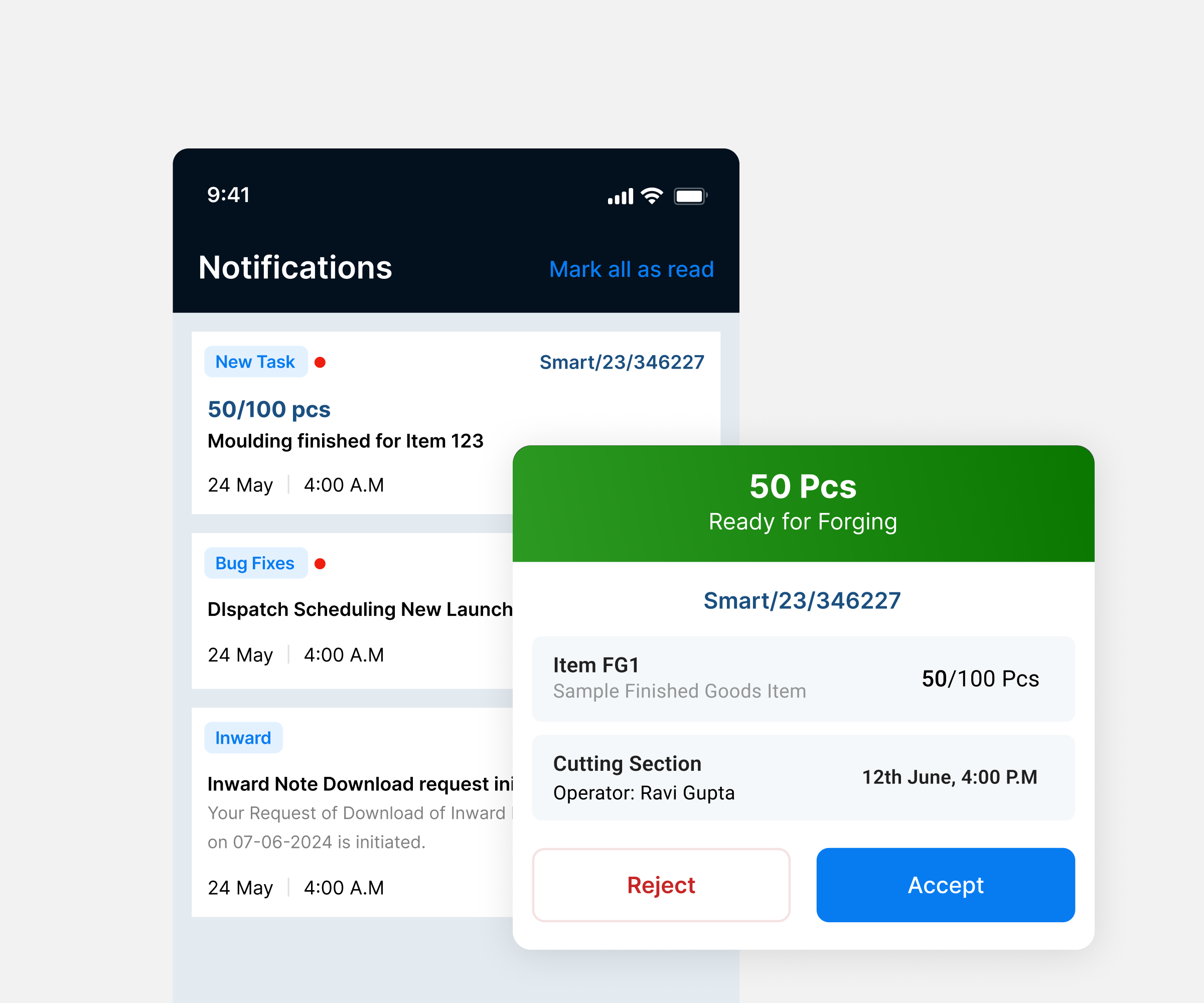

Mobile-First Production Management for Enhanced Flexibility

Empower your team to monitor and manage production operations anytime, anywhere, using a dedicated mobile app designed for seamless on-the-go efficiency.

Stay Proactive with Delay Alerts and Notifications

Receive instant alerts for delays or disruptions in production processes, allowing you to address issues promptly and maintain operational efficiency.

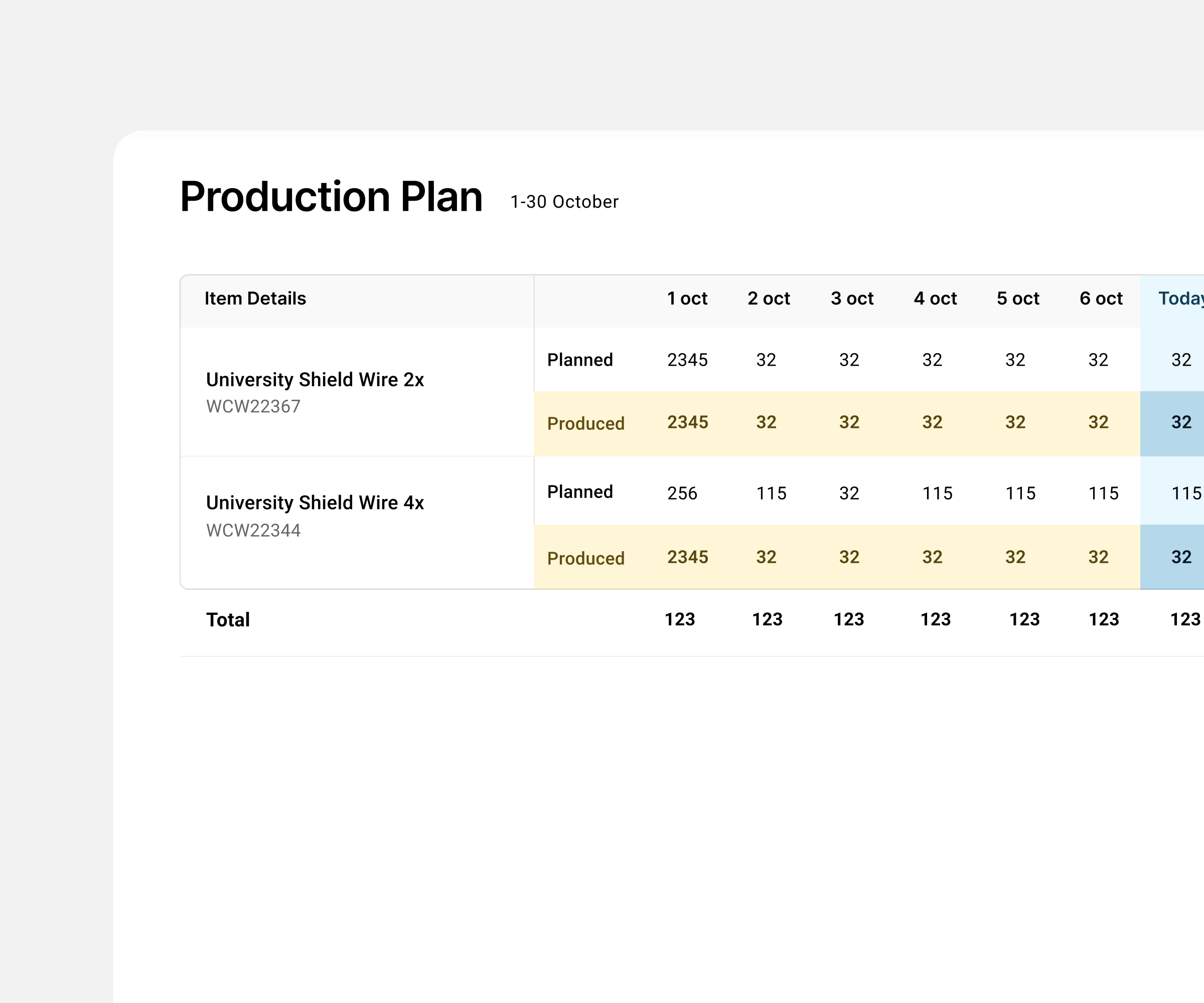

Planned vs. Actual Insights for Performance Optimization

Track and compare planned production schedules against actual outcomes to identify gaps, optimize processes, and enhance overall productivity.

We’d Love to

Hear From You

Need tailored assistance with your Manufacturing needs? Our expert team is available to help

Contact information:

Email: sales@manufapp.com

Phone: +91 97171 15905

Benefits of our Production Operations Management Software

- With standardized operational processes, quality management, and visibility into operational processes, businesses will have improved quality and regulatory compliance of production outputs.

- Analytics-based capacity planning and production, KPIs monitoring will increase operations reliability.

- Accurate inventory planning and automatic alerts for replenishment reduced inventory costs.

- With operations monitoring and tools, manufacturers will be alerted of operational issues and then can plan resolution.

- Manual and automated collection and analysis of operational data that reduced reporting latency

- The software facilitates automated request, production, and purchase order requests, maintenance requests, and communication tools lead to improved productivity and better collaboration of operations’ employees.

Our production and management software if used efficiently will lead manufacturing businesses to several accomplishments that will take the business to a great height

Significance of our Production and Operations Management Software

Our production and management software can be integrated with other software platforms that a business may be using. Thereby the different functions in a factory can all be brought on a common level.

Ensure Data Consistency – Our reliable production and management software ensures businesses have accurate and consistent data so that they can confidently make decisions with the latest information available.

High Visibility into operational data – The software facilitates real-time data collection and analysis that leads to monitoring the operations and proactively reacting to any operational delays and product defects.

Advanced-Data Analytics – Advanced data analytics allows production and operation staff to accurately plan resource utilization and quickly react to the risks that may impact the product or service quality.

Advanced-Data Security – The software having advanced data security protects sensitive operations data and revenue-related data with authorized user access, user activity logs, and data encryption.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=”.vc_custom_1712913996412{margin-top: 40px !important;}”]

Why do Businesses need Production and Operations Management System?

Manufacturing businesses today rely on production and operation management systems to run, monitor, and schedule daily activities. Using our software businesses will know how their procedures and performance align with their KPIs and make adjustments when required. Some of the other reasons why our software will be beneficial for businesses are:

Increase productivity and reduce waste – Production, and operation management system will ensure that the production and fulfillment process is effectively running and organizations can also enhance their existing workflow and get feedback from customers and team members in real-time. It also allows businesses to optimally manage human resources during the production or distribution process to maximize return on investment. Businesses can cut unnecessary expenses that occur due to slow and ineffective business processes. The software will help businesses strike the right balance between increasing productivity and effective inventory control.

Automate recurring processes and consolidate data – Our software will ease the data collection and consolidation that will further aid in better decision making. Operations managers can rely upon data to monitor their production capacity and enhance their production and distribution lifecycle for improved customer satisfaction and better ROI. Repetitive and time-consuming business processes can be automated by the managers and they can considerably save time by delegating recurring and labor-intensive tasks to software.

Facilitate cooperation and improve collaboration – Our software will allow different departments of an organization to work together to achieve common business goals. Besides, also encourages healthy collaboration among coworkers that improve operational process management for better results. The sales and marketing departments can work together to optimize an existing campaign to generate more leads. This software enhances communication, eliminates information silos, and eases information sharing, and also makes seamless collaboration with external partners.

Features of our Production and Operations Management Software

Our production and operations management software help organization streamline their business process and also allow them effectively manage the manufacturing and distribution process. It also improves their process and automates repetitive tasks to eliminate operational bottlenecks. Some of the standout features of our software include:

Analytics – our software is efficient in collecting data and provides the organization with data-backed reports that allow their team makes the right business decisions. With detailed analytics, businesses will also have insights into their business operations and production capacity. Organizations can also identify high-performing actions and change strategies that are not driving results.

Cross-app integration – Our software makes cross-company data integration smooth and will ease the collaboration and sharing of data to other platforms. Besides, it also makes sharing of data across other programs and will help reduce human error.

Intuitive Design – Our software has an easy-to-use and navigate interface that will allow the team to easily make changes without any hassle. The software can also be easily customized to fit the company’s business operation.

Security – Our software comes with impenetrable security, as it is equipped with database encryption that helps prevent data breaches and malware attacks.