Transform Your Factory with AI-Powered Intelligent Monitoring System

Our Intelligent Monitoring System combines AI-driven camera vision, IoT, and sensor integrations to provide real-time insights into your factory operations. With predictive analytics, early anomaly detection, and seamless ERP connectivity, IMS helps you prevent bottlenecks, and maintain total control over your production floor.

What we do

Transform Your Factory

Explore tailored modules, innovative solutions, and valuable resources designed to accelerate your business growth.

Products

Complete Customizable Configuration

Your operations are unique—your software should be too. Manufapp offers custom configuration options to fit your workflows, processes, and business needs, ensuring a seamless and efficient system tailored just for you.

Flexible Integration & Scalability

Tailored software solutions designed exclusively for your business needs. From efficient workflow management to customer engagement tools to drive productivity.

AI & Machine Learning Customization

Train Intelligent Monitoring System Solution Page's AI models on your factory's specific data to improve detection accuracy for defects, anomalies, and predictive maintenance. Implement custom AI algorithms for advanced insights.

Solutions

Our Suite of Module.

Ready to Power Your Operations.

Explore a spectrum of modules meticulously designed to empower your manufacturing operations.

Manufacturers Love ManufApp

Trusted by manufacturers to drive digital transformation.

Help Center

Got a question?

Get your answer

Quick answers to questions you may have. Can't find what you're looking for? Reach out to us to get more clarity.

IMS connects through IoT sensors, OPC servers, industrial cameras, testing equipment, and ERP integrations, ensuring seamless real-time monitoring without disrupting existing workflows.

IMS is compatible with a wide range of industrial sensors, including temperature, pressure, vibration, humidity, and power meters, along with IoT-enabled weighing machines and testing equipment.

Yes, IMS supports integration with major ERPs like SAP, Oracle, and Microsoft Dynamics, allowing synchronized data exchange for inventory, production, and quality management.

IMS uses AI-driven image recognition and machine learning algorithms to monitor machine operations, detect anomalies, track worker activities, and ensure safety compliance.

Yes, IMS analyzes real-time machine data to predict potential failures and bottlenecks, enabling proactive maintenance and reducing unplanned downtime.

MS sends instant alerts via SMS, email, dashboards, or API-based notifications whenever critical parameters exceed defined thresholds, ensuring quick action.

IMS is compatible with OPC UA, MQTT, Modbus, and REST APIs, ensuring secure and scalable data exchange between machines and software platforms.

Yes, IMS supports multi-factory and multi-location deployments, providing centralized monitoring and analytics across different plants from a unified dashboard.

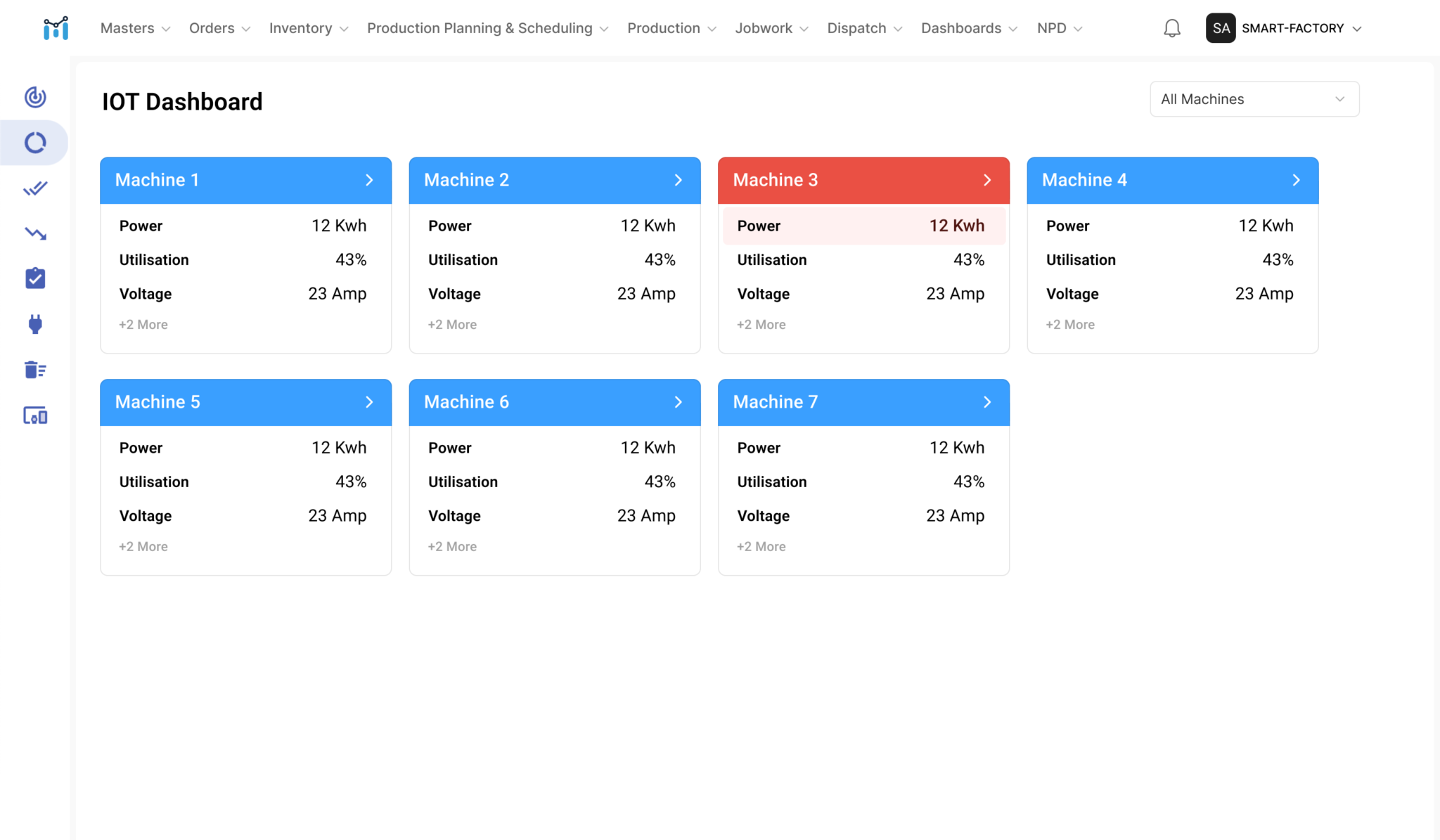

IMS offers customizable dashboards and reports, including real-time production insights, energy consumption trends, quality analytics, and machine efficiency metrics.

IMS follows strict security protocols, including end-to-end encryption, role-based access control, and secure cloud or on-premise deployment to safeguard factory data.

Make Your Manufacturing Intelligent Now

Need tailored assistance with your Manufacturing needs? Our expert team is available to help

Contact information:

Email: sales@manufapp.com

Phone: +91 97171 15905