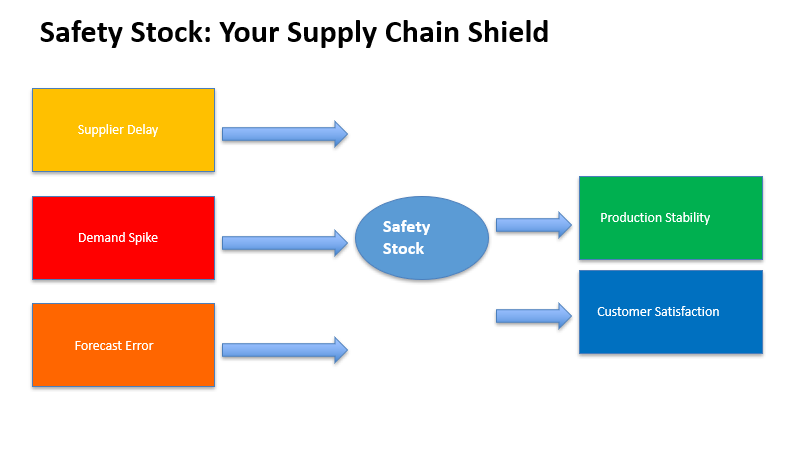

In manufacturing, even one missing part or piece can completely halt production. It is common for supplies to be late, demand to spike suddenly, or forecasts to unexpectedly prove wrong. Safety stock is a fundamental buffer that helps keep businesses running when things don’t go as planned.

This blog will explain safety stock and its importance and provide some simple and basic examples to help calculate it accurately.

What is a Safety Stock?

Safety stock is inventory kept in reserve to protect against supply chain disruptions. That could include things like:

- Supplier delays

- Sudden spikes in customer demand

- Inaccurate or aggressive forecasts

Safety stock keeps manufacturers running when demand deviates from the norm or supply is delayed. It is the cushion that protects you from uncertainty and your customers from frustration.

Why Safety Stock Is Critical in Manufacturing

Without safety stock you risk:

- Downtime in production

- Non-delivered orders

- An increase in customer complaints

- The need for an emergency purchase at a higher cost

On the flip side, the right amount of safety stock allows you to:

- Manage unexpected changes in supply or demand

- Meet service level requirements

- Lower last-minute buying

- Avoid unplanned downtime

In the end, safety stock helps stabilize your production process and increase resiliency in your supply chain.

How to Calculate Safety Stock

There is no single method for calculating safety stock. How you calculate it depends on the needs of your business, the variability of demand, and supply fluctuations. Here are three of the most common methods:

1. Fixed Safety Stock Method

This is the easiest method. A business keeps a fixed quantity of safety stock based on its historical experiences and risk profile.

- Example:

If your supplier is consistently late, you may keep an additional 100 brake pads in stock at all times. - Best for:

Businesses with stable demand and consistent supplier behavior. - Not suitable for:

Fast-moving consumer goods or high-variability environments.

2. Average Demand and Lead Time Variation Method

This method uses average demand, lead time, and lead time variability.

Formula:

Safety Stock = Z × σLT × D

Where:

- Z = Service level factor (e.g., 1.65 for 95% service level)

- σLT = Standard deviation of lead time

- D = Average daily usage

Example:

If daily demand is 100 units, lead time variation has a standard deviation of 2 days, and service level is 95% (Z = 1.65):

Safety Stock = 1.65 × 2 × 100 = 330 units

This method enables a more data-oriented approach to buffer stock forecasting.

3. Dynamic ERP-Based Safety Stock

Modern ERP systems calculate safety stock based on real-time business intelligence. These calculations consider:

- Historical demand trends

- Forecasting accuracy

- Supplier performance and lead times

- Business-specific risk factors

Example:

A production-based ERP (like ManufApp) can use rolling demand averages and recent supplier data to suggest safety stock levels. These values integrate into the material requirement planning (MRP) process.

Best for:

Companies that want to automate planning and reduce manual workload while improving accuracy.

Essential Inputs for Safety Stock Planning

To calculate safety stock effectively, you need:

- Average daily or weekly demand

- Standard deviation or uncertainty in lead time

- Desired service level (90%, 95%, etc.)

- Supplier performance data

- Historical stockout incidents

With this information, companies can build a reliable buffer strategy.

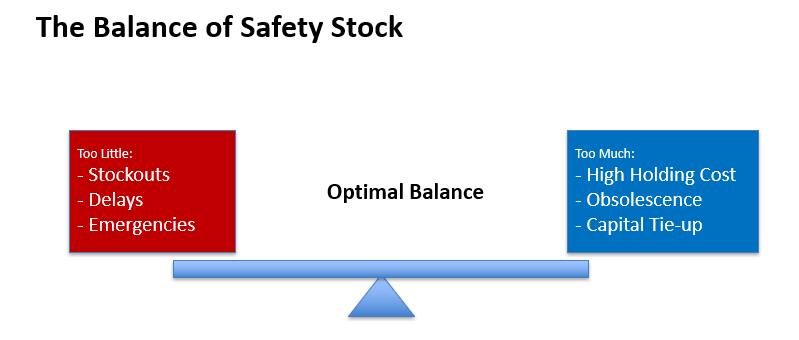

What Happens if You Get Safety Stock Wrong?

Getting safety stock wrong can lead to serious operational issues.

If too little safety stock exists:

- Frequent stockouts

- Production delays

- High emergency procurement costs

If too much safety stock exists:

- Higher holding and storage costs

- Risk of materials becoming obsolete or expired

- Working capital tied up in slow-moving stock

Striking the right balance is key—enough protection to prevent disruptions but not so much that it inflates costs.

Guidelines for Managing Safety Stock

To maintain optimal safety stock levels, follow these steps:

- Review safety stock levels quarterly

- Adjust inventory for seasonality and promotions

- Regularly evaluate supplier performance metrics

- Use ERP recommendations but always validate manually

Following these practices helps ensure cost-effective and reliable inventory management.

Conclusion

Safety stock is not a luxury—it’s a necessity in modern manufacturing. With accurate data, appropriate calculation methods, and intelligent ERP tools, companies can:

- Minimize disruptions

- Maintain high service levels

- Reduce procurement and storage costs

A well-planned safety stock strategy leads to a more resilient, efficient, and competitive manufacturing operation.

Need Help?

Do you need assistance with implementing safety stock logic into your ERP system?

Contact the ManufApp team today to implement strategic inventory planning.