The electrical industry is constantly evolving and growing, and with it comes the need for efficient production management. That’s where production software comes in. Production software or production management system is a powerful tool that can help streamline operations, increase productivity, and improve overall business performance. In this blog post, we will take a closer look at what production software is, its functionalities, and the benefits of using cloud-based production software. We will also delve into how to choose the right production software for your business by identifying your requirements and assessing scalability and user interface.

Additionally, we will discuss the advantages of integrating ERP with production software or production management system for centralized data management and improved communication between departments.

Lastly, we will explore how production software can be used to enhance supply chain management through inventory management and forecasting tools to optimize production and reduce waste.

What is Production management software

Production management software is a powerful tool designed to streamline and optimize the entire production process within a business or manufacturing environment. It acts as a centralized hub that integrates various aspects of production, including planning, scheduling, inventory management, resource allocation, and quality control. With this software, organizations can efficiently monitor and control their production activities, ensuring smooth operations and improved productivity.

One of the primary functions of production management software or production management system is to facilitate planning and scheduling. It enables users to create detailed production plans, allocate resources effectively, and set realistic deadlines. By visualizing the production workflow and identifying potential bottlenecks, the software helps optimize resource utilization and minimize production downtime. Such software becomes more relevant in Electrical industries where there are multiple stages of production before the finished product is manufactured.

Overall, production management software empowers businesses with the tools and insights needed to enhance operational efficiency, reduce costs, and maximize output. It fosters better coordination among teams, reduces wastages, improves communication, and streamlines workflows, ultimately leading to increased profitability and competitiveness in the market.

According to a report by PR News Wire* Market size of Production Software in Electrical Industry is set to grow by USD 14.67 billion during 2021-2025, Technavio’s latest market research report estimates the digital manufacturing in the electrical and electronics market to register a decelerating CAGR of almost 18%.

Products Manufactured by Electrical Industry

The electrical industry encompasses a wide range of sectors and segments, each serving different purposes and markets. Here are some common types of sectors within the electrical industry:

Wire and Cables : This industry is involved in the manufacturing of various types of wires, cables, and related products. These products serve a wide range of applications across industries. For example Automotive cables which are specifically designed for use in vehicles. They include battery cables, wiring harnesses, and specialized cables for applications like automotive electronics, lighting, and power distribution.

Other wires and cables include Building wires which are used for electrical wiring within residential, commercial, and industrial buildings. They provide electrical power and lighting connections to outlets, switches, and electrical equipment.

Same like above there are many different types of products manufactured by wires and cables like Power cables, Control cables, Communication cables, Industrial cables etc.

Switchgear: The switchgear industry is responsible for the manufacturing of various electrical equipment and devices used for controlling, protecting, and isolating electrical circuits. These products play a crucial role in power distribution systems and electrical installations.

Another major product manufactured are Switchboards, these are electrical distribution panels that house and protect various switchgear components. They provide a central point for power distribution and include devices such as circuit breakers, switches, metres, and relays.

Along with switchboards this industry also manufactures Switches. Switches play a fundamental role in controlling the flow of electrical current in various applications. They are essential components in electrical circuits and systems, offering functionality such as circuit opening and closing, interrupting power, and enabling user control.

Similarly other products manufactured are Distribution Boards, Contactors, Protective Relays etc.

How production management software can benefit Electrical Industry

Production management software can bring numerous benefits to the electrical industry by optimizing and streamlining manufacturing processes, enhancing operational efficiency, and improving overall productivity. Here are some key ways in which production management software can benefit the electrical industry:

Efficient Production Planning and Scheduling: Production management software enables effective planning and scheduling of production activities. It takes into account factors such as resource availability, material requirements, and order priorities to optimize production sequences. This ensures that production is well-organized, minimizing downtime and maximizing output.

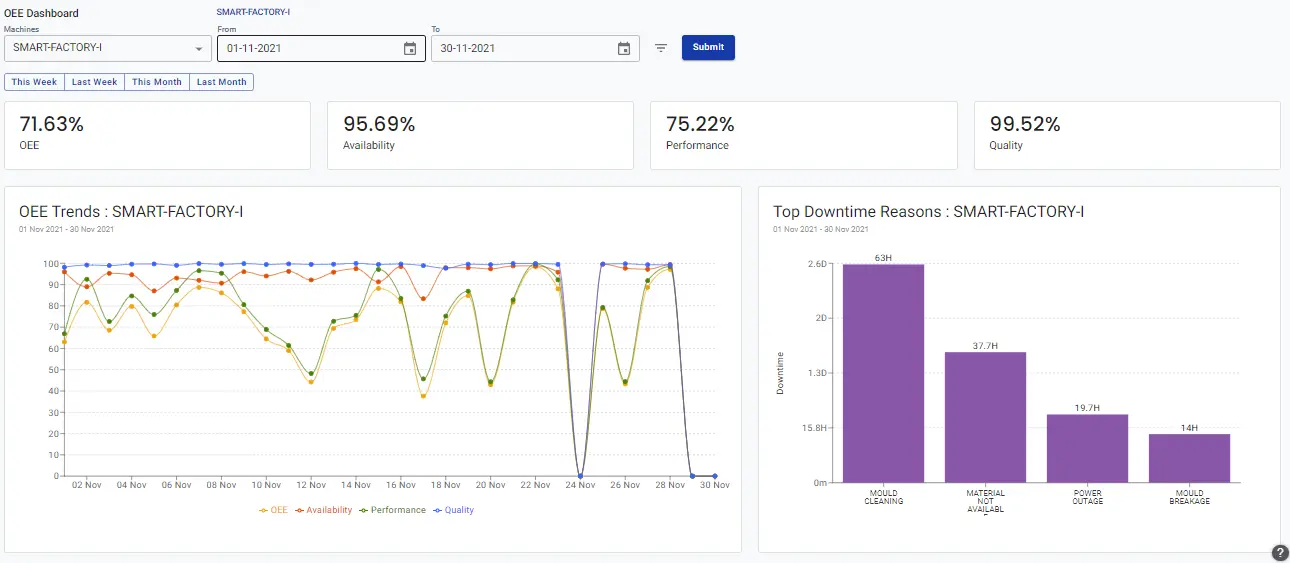

Real-time Production Monitoring: Production management software provides real-time visibility into production operations. It collects data from various sources, such as machines, sensors, and operators, allowing for real-time monitoring of key performance indicators (KPIs). This helps in identifying bottlenecks, optimizing production processes, and making data-driven decisions for continuous improvement.

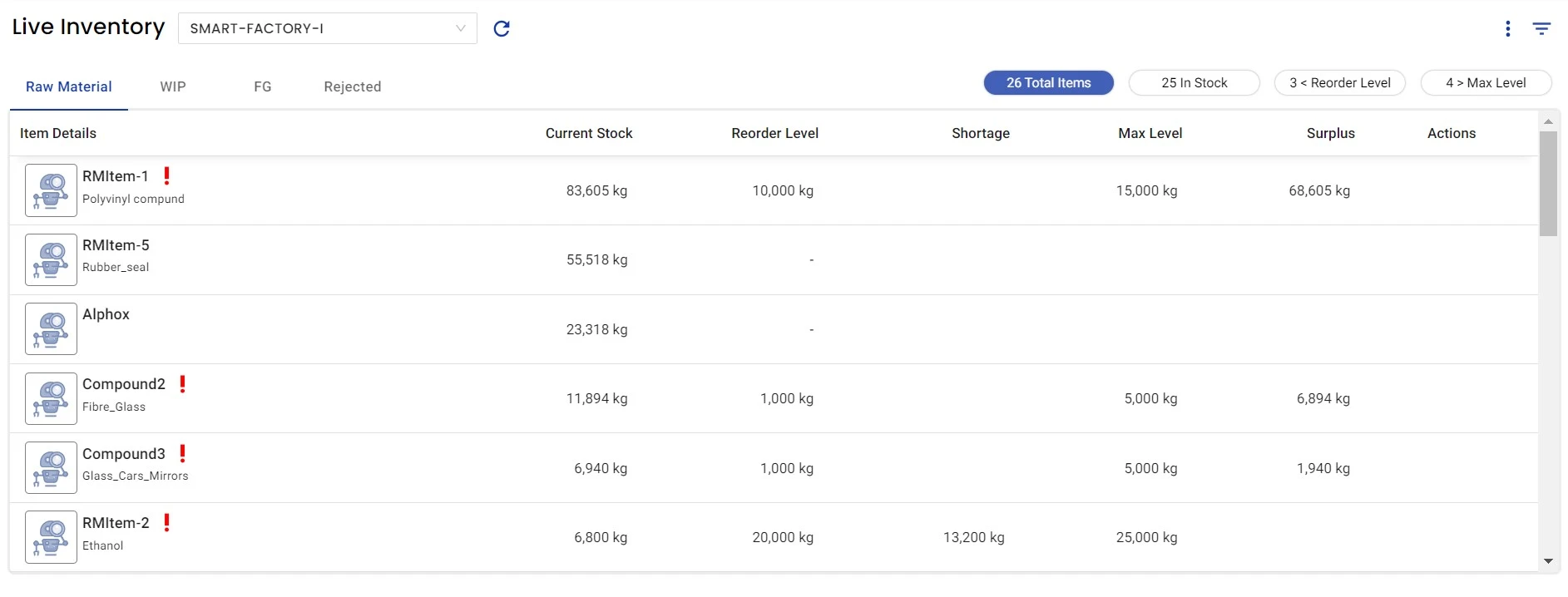

Inventory Management and Material Tracking: Production management software helps in managing inventory levels and tracking materials throughout the production cycle. It provides visibility into inventory status, facilitates accurate demand forecasting, and ensures timely procurement of materials. This reduces stockouts, minimizes excess inventory, and improves overall supply chain efficiency.

Quality Control and Compliance: Production management software includes features for quality control and compliance management. It helps in implementing quality control processes, capturing inspection data, managing non-conformances, and ensuring compliance with industry standards and regulations. This improves product quality, reduces rework, and enhances customer satisfaction.

Resource Utilization Optimization: Production management software helps optimize the utilization of resources, including machines, equipment, and labor. It enables effective resource allocation, balancing workloads, and minimizing idle time. This improves operational efficiency, reduces costs, and increases overall productivity.

Workforce Management: Production management software assists in managing the workforce effectively. It helps in tracking employee assignments, monitoring productivity, and capturing labor data. This enables better resource planning, skill utilization, and performance management, leading to increased productivity and employee satisfaction.

Data Analytics and Reporting: Production management software provides robust data analytics and reporting capabilities. It generates comprehensive reports, performance dashboards, and data visualizations, allowing for in-depth analysis of production data. This helps in identifying trends, uncovering insights, and making data-driven decisions for process optimization and continuous improvement.

Integration with Enterprise Systems: Production management software can integrate with other enterprise systems such as Enterprise Resource Planning (ERP) software, Customer Relationship Management (CRM) systems, and Supply Chain Management (SCM) solutions. This enables seamless data flow, streamlines processes, and facilitates end-to-end visibility and collaboration across different departments.

Overall, production management software offers the electrical industry significant benefits, including improved production planning, real-time monitoring, optimized resource utilization, enhanced quality control, and better data-driven decision-making. By leveraging these capabilities, the electrical industry can achieve higher operational efficiency, reduce costs, deliver high-quality products, and gain a competitive edge in the market.

The Manufacturing ERP also benefits other industries in the Market, like our blog on role of MES in Heavy Engineering Industry puts a light on the same.

ManufApp experience with its Customers

We had the privilege to work with some of the finest industries in their platform who have been using our services and satisfied with our products. Few of them are

G.K. Winding Wires Limited is the leading manufacturer of Copper & Aluminium Enamelled Winding Wires in India, marketed under its brand GEEKAY. The market for copper winding wires is over 2.5 lac MT per annum and they are one of the leading players in the organized sector.

GeeKay is managing its entire shopfloor using ManufApp Production Management System

C&S- C&S is amongst the top 4 players in the switchgear business segment and a market leader in the busbar business with more than 50% share in the Indian market. C&S is leveraging ManufApp for its Moulding unit.

Some other customers include RMC Switchgears, AEC Airon, Expert Engineers, SGI (Bhiwadi), Supermac (provider of wire extrusion machines).

How to choose the right production software for your business?

When selecting production management software for your business, consider its size and requirements. Choose software that integrates with other tools you use, has a user-friendly interface, and customizable features. Research and ask for input from other companies in your industry before deciding.

Identifying your business requirements for production software

To identify the right production software for your manufacturing business, it’s crucial to first assess your business requirements. This involves identifying your specific needs and ensuring that the chosen software is scalable, user-friendly, and compatible with your existing systems. Look for features such as inventory management, scheduling, and quality control to improve visibility into your manufacturing operations. By comparing different cloud-based production software options like Katana or MRPeasy, you can improve workflow efficiency while reducing bottlenecks in the production process.

Assessing the scalability of production software

When it comes to assessing the scalability of production software systems, it’s important to have a clear understanding of your business needs and goals. Research and compare different options based on features, pricing, user reviews, and compatibility with existing systems. To ensure smooth implementation and usage, choose a software provider with reliable customer support and training resources. Always consider future business growth when assessing scalability. By implementing scalable production software systems like cloud-based manufacturing software or ERP integration for real-time data visibility on shop floor bottlenecks can be identified timely ensuring increased profitability. Manufacturers should chose Manufacturing ERP in place of Traditional ERP, for better understanding please follow the link below

Why do Manufacturers need Manufacturing Execution System in addition to Traditional ERP

Evaluating the user interface of production software

To evaluate the user interface of production software, businesses should consider their needs for scalability, compatibility with existing systems, and customer support options. Streamlining manufacturing operations through a user-friendly system is crucial for success in the industry. By choosing a cloud-based solution offering real-time data visibility on workflows, bottlenecks, and production schedules with modules like CRM or ERP software systems can help optimize raw material procurement to payroll and ensure profitability through quality management, shop floor control, accurate data on resource allocation & more.

Conclusion

Production management software is an essential tool for businesses in the electrical industry to streamline their operations and increase productivity. With cloud-based options, businesses can enjoy the benefits of remote access, real-time data tracking, and improved collaboration. When choosing the right production software for your business, it’s important to identify your specific needs and assess scalability and user interface. Integrating ERP with production software offers further advantages such as centralizing data management and improving communication between departments. Utilizing production software to improve supply chain management through enhanced inventory management and forecasting tools can optimize production while reducing waste. If you’re ready to take your business to the next level with production software, contact us for a free demo today.