You’ve been running your manufacturing business for years and have a system in place that seems to work. But if you’re still relying on spreadsheets, outdated software, and manual processes to manage your operations, it may be time for an upgrade. Production management software or production management system can help take your company to the next level. Here are the reasons you should consider implementing a smart manufacturing platform sooner rather than later.

Increased Visibility Into Your Operations

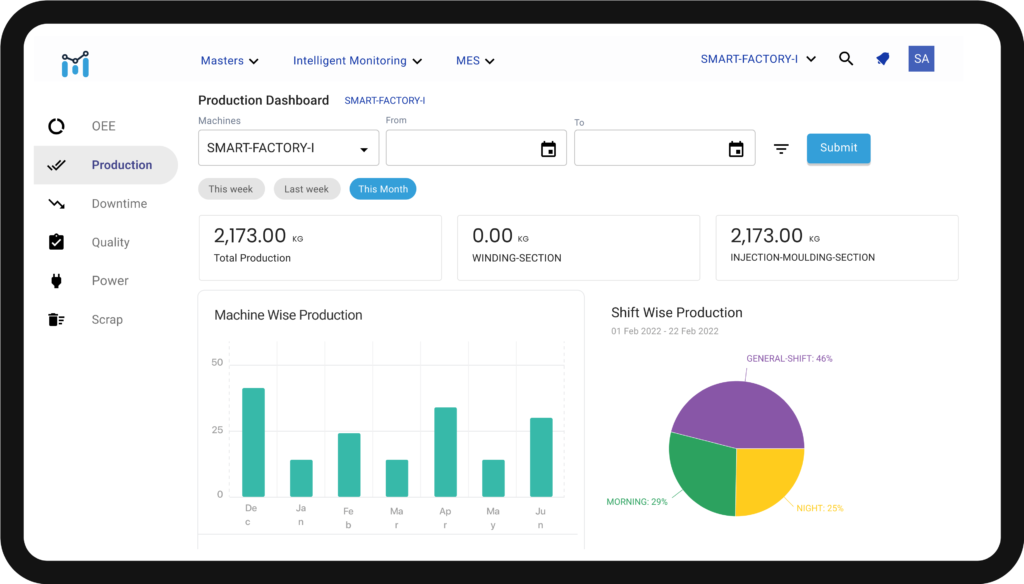

Implementing production management software gives you an all-access pass to see what’s really going on in your operations.

With live data monitoring and reporting, you’ll gain visibility into everything from inventory levels to resource allocation to productivity. No more guessing games or running around putting out fires. You’ll have the insights to make strategic decisions and optimize processes.

For example, live dashboards and KPIs let you identify bottlenecks and inefficiencies on the factory floor so you can make adjustments to improve flow and output. Real-time alerts notify you the second an issue arises so you can take corrective action before it impacts quality or delivery times.

You’ll also gain insight into your true costs and profit margins. Accurate data on labor, materials, and overhead tied to each job provides the transparency you need to properly price products and services. Make data-driven decisions on what’s working, what’s not, and how to improve.

With role-based access, you can share reports and dashboards with colleagues across departments. Everyone stays on the same page and can work together towards company-wide goals. No more lack of communication or confusion on objectives.

With Advanced analytics and reporting equipment you can optimize your operations, reduce waste, control costs, and get skyrocket productivity. Isn’t gaining complete visibility into your business worth investing in production management software? The benefits to your bottom line will be huge.

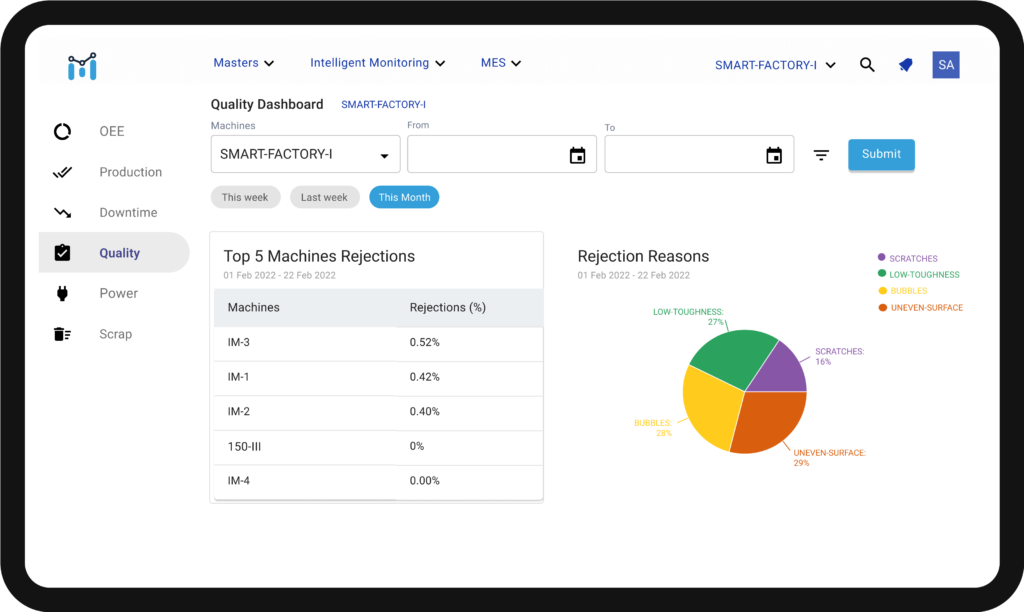

Improved Quality

Implementing a smart manufacturing platform in your factory is one of the best ways to improve quality and ensure compliance. Here are a few reasons why:

Production management software or production management system gives you an integrated view of your entire manufacturing process from start to finish. It helps track raw materials, work in progress, and finished goods in real time so you have full visibility and traceability. This makes it much easier to identify quality issues early and take corrective action.

Smart tools like automated inspection systems, AI-based defect detection, and predictive analytics help boost quality by reducing human error and waste. They can spot issues that people might miss and alert you to potential problems before they arise. Our blog on COPQ (Read here) will highlight more on the topic.

When you have a single source of truth for all your manufacturing and quality data, it leads to consistency and standardization. Everyone is working from the same set of procedures and specifications. And with role-based access, you can ensure people only see what they need to do their jobs.

With reference to report on *asq.org, many organisations will have true quality-related costs as high as 15-20% of sales revenue, some going as high as 40% of total operations. A general rule of thumb is that costs of poor quality in a thriving company will be about 10-15% of operations. Effective quality improvement programs can reduce this substantially, thus making a direct contribution to profits. You can read our blog Rise of Smart Factory in today’s Digital World – What Impact & Benefits it brings for Manufacturing Industries? for more information on the smart factory (MES) benefits.

In the end, a smart factory platform leads to higher overall equipment effectiveness (OEE), lower costs, and happier customers. By optimizing your processes and quality management with the help of software and technology, you’ll make more compliant and consistent products with fewer mistakes and less rework. And that’s a win-win for any manufacturer.

Maximized Resource Utilization

Production management software helps manufacturers maximize their resource utilization in several key ways:

Reduce Waste

With real-time data on resource allocation, you can identify areas of excess waste and make adjustments. See which machines are underutilized or processes that are inefficient, and make changes to optimize productivity. Trim down time spent waiting between steps or minimize excess raw materials. Over time, these small improvements add up to major cost savings and a leaner operation.

Balance Supply and Demand

Having visibility into your entire production flow allows you to align supply and demand. Gage how much inventory you have of each component and ensure you have enough to meet production targets without overstocking. If demand spikes unexpectedly, you can see where there are extra resources to allocate. This helps avoid costly shutdowns due to lack of materials or finished goods sitting in the warehouse waiting to ship.

Improve Scheduling

Smart scheduling tools provide recommendations to keep your facility running efficiently. They can suggest the optimal order and timing of jobs based on priorities, machine capabilities, and staffing levels. Easily make changes to the schedule in real-time to adapt to unforeseen circumstances. With automation, you spend less time manually scheduling and shuffling resources around to keep projects on track.

Increased Uptime

When machines go down, it disrupts the entire production flow and costs money. With connected devices and sensors, you receive alerts as soon as there is an issue with any equipment on the floor. Maintenance staff can then respond immediately to get machines back up and running as fast as possible. Some platforms even have predictive capabilities to foresee potential problems before they happen.

Keeping a close watch on how you utilize resources is key to maximizing productivity and profitability. Production management software gives you the tools and insight to minimize waste, balance supply with demand, improve scheduling, and increase equipment uptime. Leveraging technology to gain a holistic, real-time view of operations helps manufacturers do more with less and gain a competitive advantage.

Reduced Waste and Costs

Production management software can significantly reduce waste and lower costs for manufacturers.

Reduce Excess Inventory

Carrying excess inventory ties up your capital and space. With production management software, you’ll have a real-time view of raw materials, work in progress, and finished goods. This visibility allows you to optimize stock levels and avoid overstocking. You’ll purchase raw materials just in time for production schedules and ship finished goods as soon as they’re ready. Lower inventory levels mean less money tied up in excess stock and smaller storage space requirements.

Minimize Scrap and Rework

Smart manufacturing software provides visibility and control over your production processes. You can closely monitor operations to detect quality issues and inefficiencies early. Make changes to reduce scrap, defects, and instances where products need reworking. The software may even use predictive analytics to forecast potential problems so you can take corrective action before they impact production. Minimizing scrap and rework leads to substantial cost savings through higher quality and yields.

Streamline Processes

Inefficient processes waste time, money, and resources. Production management software gives you the tools to analyze how work flows through your facility. You can spot bottlenecks, redundancy, and idle time. Then, you can make data-driven changes to optimize sequences, balance workloads, and speed up cycle times. Optimized, streamlined processes increase throughput and productivity, allowing you to produce more with less.

Automate Where Possible

Smart manufacturing software integrates with industrial equipment and automation like robotic arms, conveyor belts, and sortation systems. Connecting and coordinating devices can help reduce reliance on manual labor for routine, repetitive tasks. Automating processes like materials transport, quality inspections, and order fulfillment saves time and money while boosting accuracy. Workers are freed up to focus on more complex, value-added activities.

Here we would like to highlight a report by **Forbes which states that manufacturing developed a problem with global implications: 20% of every dollar spent in the industry is wasted – adding up to $8 Trillion, or 10% of the GWP.

Overall, implementing a robust production management solution will transform your operations by eliminating waste and inefficiency at every turn. The cost savings and productivity gains add up to a very high ROI and a sustainable competitive advantage. Your business will become faster, leaner, and ready to scale up as demand increases.

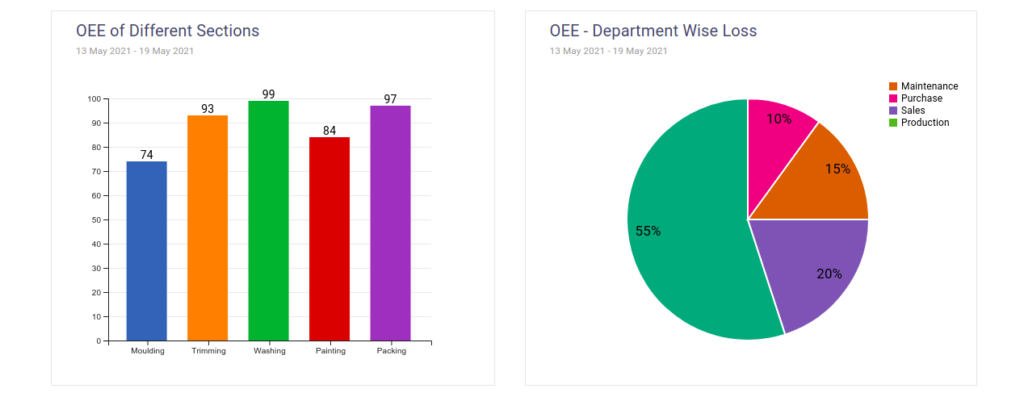

Data-Driven Decision Making

When you implement a smart manufacturing integration platform, you gain access to data and insights that simply were not possible before. With all your connected systems and processes generating information, you will have a data-rich environment to help drive impactful business decisions.

Make data-driven decisions

With reams of data at your fingertips, you can analyze trends, identify patterns, and spot opportunities or issues. Rather than relying on hunches or intuition, you can make strategic decisions based on hard facts and statistics. Some examples include:

- Optimizing machine utilization and productivity based on usage data. You will know which assets are underperforming and make changes to improve overall equipment effectiveness (OEE).

- Adjusting staffing levels and schedules in response to production volume data. You can ensure you have the right number of workers at the right time to meet customer demand.

- Identifying quality problems through detailed analytics on defects, scrap, and yield rates. You can then implement corrective actions to fix the issues, reduce waste, and boost quality.

- Developing data-driven pricing strategies based on costs, margins, and customer demand. You will have clear visibility into the factors impacting your profitability.

- Improving forecast accuracy by analyzing historical demand patterns, sales trends, and external factors like economic indicators or weather events. More precise forecasting means you can plan resources and inventory more effectively.

Conclusion

So there you have it, six compelling benefits of production management software that can transform how your manufacturing business operates. With real-time data visibility, automated processes, predictive insights and a centralized hub to manage it all, you’ll be able to scale faster, reduce costs, improve quality and make data-driven decisions to optimize your operations. What are you waiting for? Now is the time to take your manufacturing into the future with an Industry 4.0-ready production management solution. You’ll wonder how you ever managed without it. The only regret will be not implementing it sooner. So stop wasting time with outdated systems and spreadsheets and start reaping the rewards of smart manufacturing software today. Your business and bottom line will thank you for it.