Introduction

Whatever can be smart will become smart. We are not talking about humans but of objects. Cars that had primarily mechanical components now have more than 40% components that are electronic. From Smart Audio System, Smart Braking System, Smart Fuel Traceability in Electronic Manufacturing System and so on. Fans and Cooling Appliances come with remote control and based on temperature they can adjust their speed and coolness level. This phenomenon of converting old mechanical objects into smart devices is a mega phenomenon and will continue for another 50-100 years.

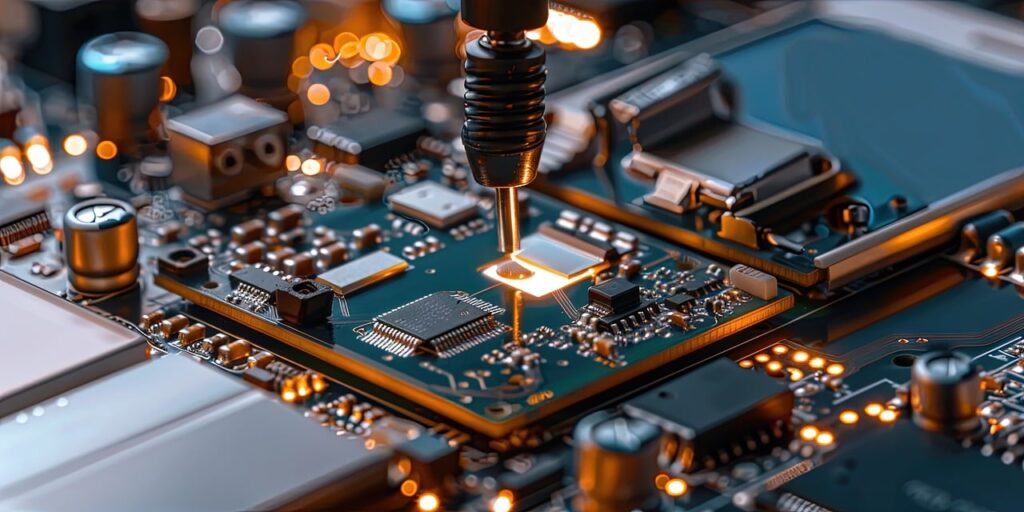

What does this mean in terms of components that are used to manufacture these objects? With devices, appliances and everything else becoming smart, more and more objects will require state of the art electronic components. The electronic components are capable of transmitting information and in a way intelligence to make the entire appliance intelligent and smart.

Manufacturing of Electronic Devices

The industry to manufacture various mechanical components like rotors, motors etc has been in existence for the last so many decades. The new wave of manufacturing is in the manufacturing of Electronic devices.

All these components would be manufactured by a set of processes.

Some of the Key Features of Traceability in Electronic Manufacturing

- Different devices have different designs: The electronic devices are designed for a very specific purpose. Like the design for electronic components that would go in a fan would be different from the one that would be required in the camera. One would have a temperature sensor while the other would have a vision sensor.

- Most devices would have many components: A typical motherboard would have multiple sensors and components. Most of these components are very tiny in nature and hence when they come in the factory, they come in bulk. Some of the components are like Microprocessors/Microcontrollers, Memory (RAM, ROM), Sensors, Interfaces (USB, HDMI, Ethernet), Circuitry. These components are sourced from different suppliers

- Robotic and Assembly processes are required to manufacture these electronic components. Most of these electronic components would have processes like SMT lines, Manual Insertion and Assembly. The SMT lines would essentially first pick a lot of components like resistors, capacitors etc. and place them on the motherboard. That is why these machines are also called Pick and Place machines. The throughput of these machines is calculated in terms of the number of components placed per hour or minute.

- Quality is very important: These devices would be part of critical objects and hence it is important that these components perform as per their specifications. If even one component fails, the entire appliance would need to be replaced.

Why is Traceability required in Electronic Manufacturing

Let us understand the importance of traceability through a brief case study.

An important IoT device is placed alongside 100s of machines in a manufacturing unit. The IoT device provides critical data in terms of predictive maintenance . Suppose the vibration sensor of the IoT device was faulty and is not sending the right information. The manufacturing unit might be in a remote location and such issues would lead to disruption in operations. It is important that such incidences are avoided.

Traceability is the process by which each and every component used in the manufacturing process is identified to the source. When one component fails, the manufacturer needs to find the root cause. If the root cause was related to a particular machine then it means that all the components that were produced on that machine need to be replaced. Hence the manufacturer needs to identify all the finished goods that have the traces of that machine. If she is not able to find, then there could be severe penalties either from the consumer court or from the business customer to whom that material was supplied to.

What are the benefits of Traceability in Electronic Manufacturing

A manufacturer that follows a full traceability system in her manufacturing unit would get the following benefits:

- Better compliance: Most industry bodies and government organisations have mandated full traceability. These are not nice to have but must have. These are enforced to ensure that the end customer does not get bad quality products

- Lesser rejections: The manufacturer who is following with end to end traceability will be able to identify quality issues and defects earlier in the process. This would mean that she would be able to rectify faster which in turn would mean that a lesser number of components would be produced with poor quality.

- More customer demand: Many businesses now audit before awarding a contract to the manufacturers. If a manufacturer fails in the audit process then she would not qualify in the bidding process.

- Better profitability: With more demand, lesser rejections manufacturers would be able to enjoy greater profits

Summary

With the ever changing world, demand for electronic manufacturing is growing. And so is the demand for end to end traceability. Manufacturers need to implement a robust traceability system to ensure they can grow without the worries of poor quality and desertion from the customers.

We will be discussing how Manufacturers can implement a full-fledged traceability system in electronics industry.