Efficiently Plan, Schedule, and Execute Your Production

Maximize your production capacity by automating planning and scheduling tasks, ensuring smooth workflows and minimal delays.

Manufacturers Love ManufApp

Trusted by manufacturers to drive digital transformation.

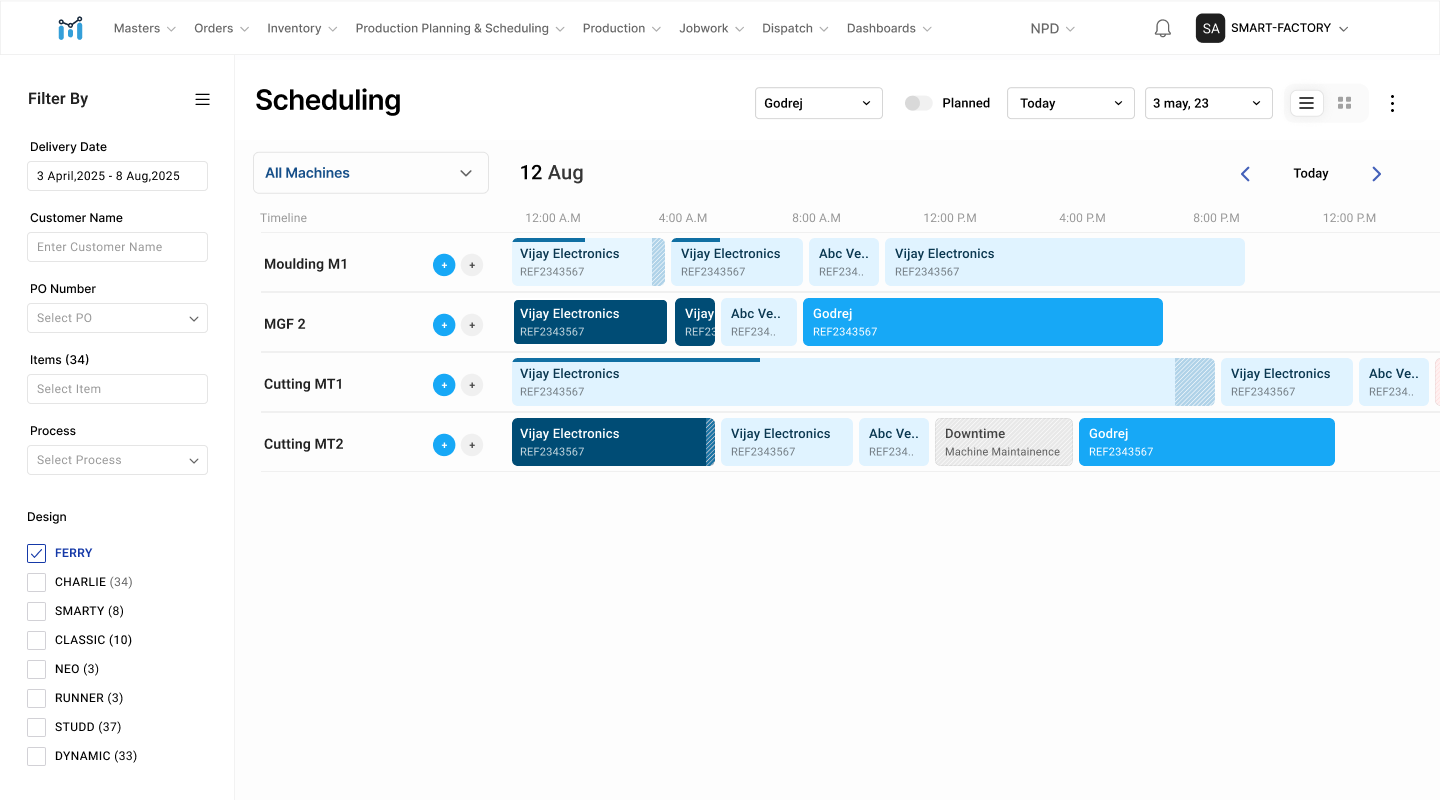

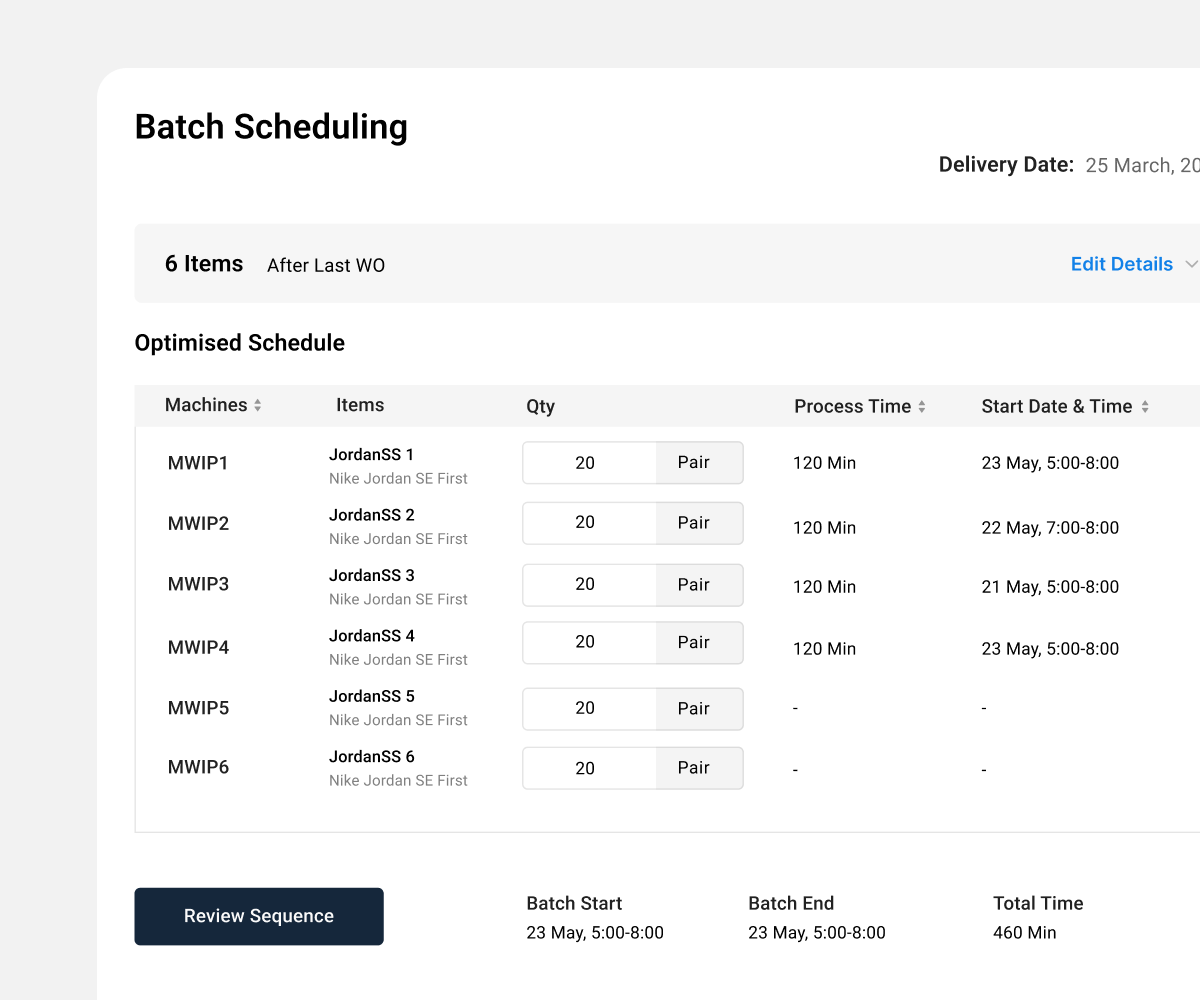

Machine-Wise Scheduling

Optimize machine utilization by scheduling production tasks specific to each machine, reducing downtime and ensuring smoother operations.

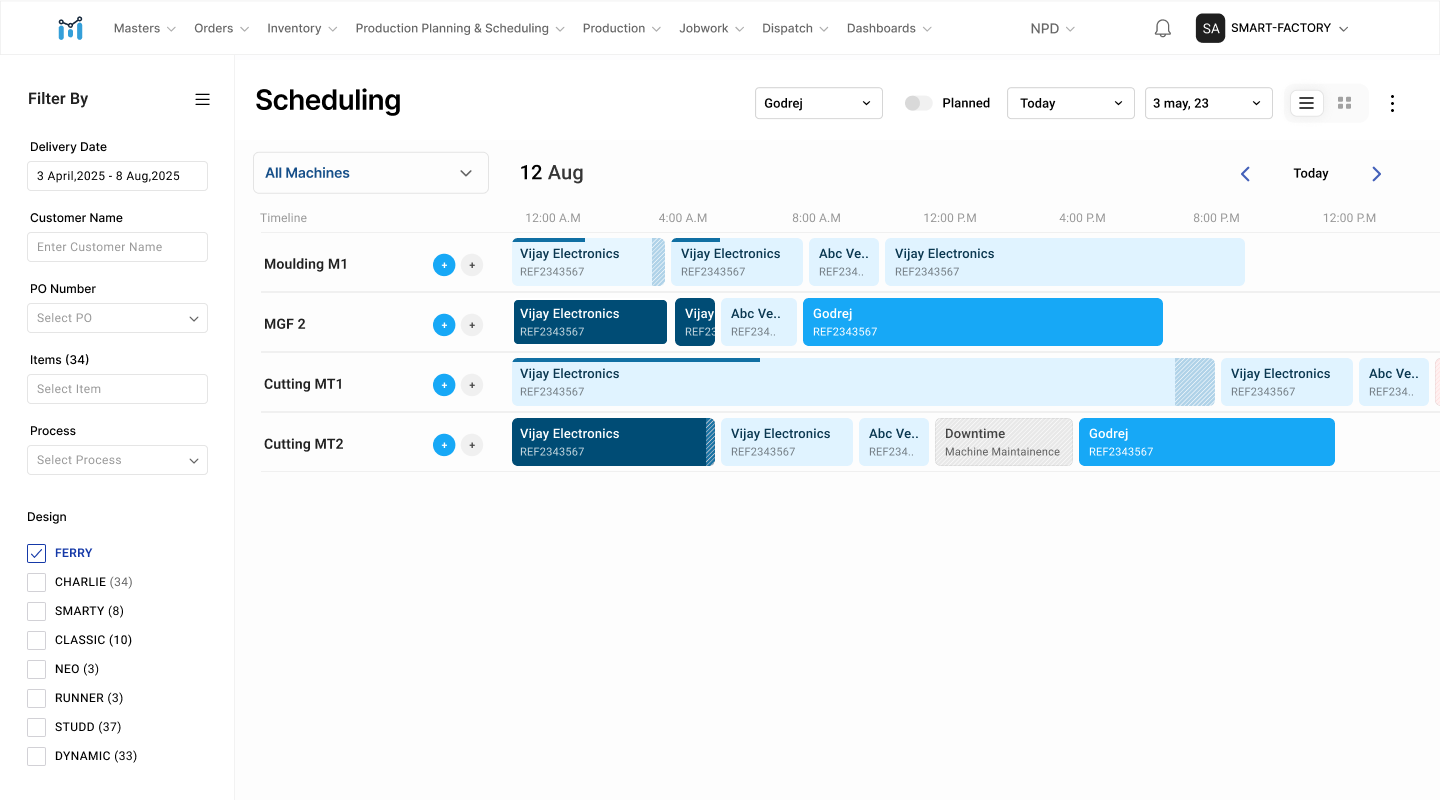

Accurate Expected Production Forecasting

Forecast production outcomes with accuracy, ensuring you meet delivery targets while optimizing resources and minimizing bottlenecks.

Effective Shift Allocation for Maximized Workforce Productivity

Allocate shifts smartly to balance workloads and ensure optimal productivity, minimizing idle time and enhancing output efficiency.

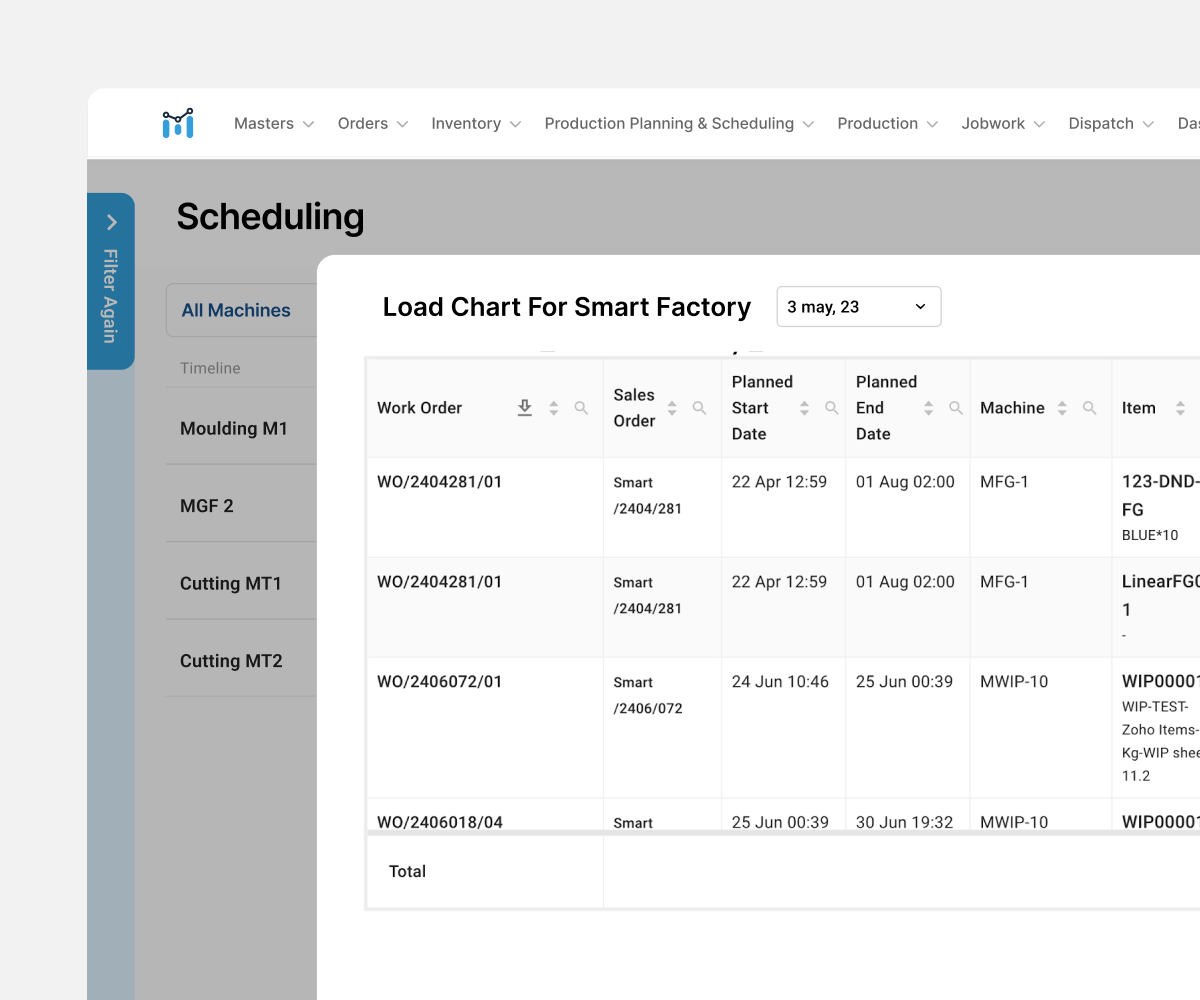

Visualize Production Capacity with Load Chart Integration

Load charts to get a clear overview of production capacity, helping you manage demand, prevent overloading, and streamline scheduling.

Planning and Control :Effective planning and control are important to meet the production goals and customers’ demands while adapting to resources.

Manufapp’s plan and control module helps you stay on top of production programs, material requirements, and order supply.

Why Plan and Control

Case provided plan and control allows makers to:

- Maximum efficiency: Ensure that all resources (materials, machines, labor) are better used.

- Stay on Track with the Production Schedule: Prevent production from being pushed back and delays in progress.

- Adapt To Change Easily: Adjust to demand shifts or supply chain disruptions swiftly.

Planning and Control Key Features:

- Intelligent Production Planning: Plan the complete cycle of production, allocate jobs optimally, and have an end-to-end view of production status.

- Material Needs Plan (MRP): Align the purchase of materials with the production program.

- Capacity Plan: Ensure that your convenience has the ability to meet the demand.

- Performance Monitoring: Track major metrics such as throughput and downtime.

With Manufapp, you get tools to fulfill the demands to plan, execute, and develop your production processes efficiently.

Make Your Manufacturing Intelligent Now

Need tailored assistance with your Manufacturing needs? Our expert team is available to help

Contact information:

Email: [email protected]

Phone: +91 97171 15905