“Manufacturing execution systems software” “MES” is significantly becoming a vital element for scheduling, planning, tracking, analyzing, and controlling manufacturing operations. With report on basis of *Insight Partners, by 2028, the global Manufacturing Execution System market size is expected to be worth $24.28 billion, growing at a 10.8% CAGR. Adopting new and advanced solutions like MES always adds value to the production capacity and quality. Despite this fact, factories are showing very little interest in the change.

As per the statistics, 48% of the organizations are resistant to any kind of change to their manufacturing setup. The clear reason behind this is that mid-size manufacturers always find themselves surrounded by several challenges relating to the change, restricting them to opt for a new solution.

This article will list some of the significant challenges that medium-size companies face while implementing MES and focus on ways to overcome them.

Let’s begin.

Basic Implementation Challenges

Let us see what common issues create obstacles in adopting the “Manufacturing execution systems software” “MES”:

1- High upfront cost, which the size of the business can ill afford.

Solution: Thankfully, nowadays many MES vendors do not ask for upfront. Most of them have a subscription-based fee structure. It means you get the installation first, observe its working, and then you pay the charges.

2- Hardware requirements, the cost to own them including maintenance are substantial

Solution: The budget for the hardware requirements is variable, based on:

- The size of the organization

- The industry manufacturer belongs to

- The geographical diversification of the company

- The package selected

Hence, if you have a small or mid-size factory, the cost will automatically be affordable. Other than that, the hardware requirements are minimal as modern MES providers offer cloud-based software. You have the dashboard which is accessible from your end to operate and manage your factory, but the data security and storage are maintained entirely by the vendor. Many vendors also offer hardware maintenance as a part of their package.

3- Very typical requirements for these manufacturing don’t fall under their standard solution package.

Solution:

Go for a customized solution. Advanced “Manufacturing execution systems software” “MES” vendors provide custom- made MES software, which is based on the individual requirements of the manufacturing unit.

As a result, the solution offered addresses the exact needs and challenges in the manufacturing process and hence propels your production scale.

4- Long implementation cycle and associated cost of implementation.

Solution:

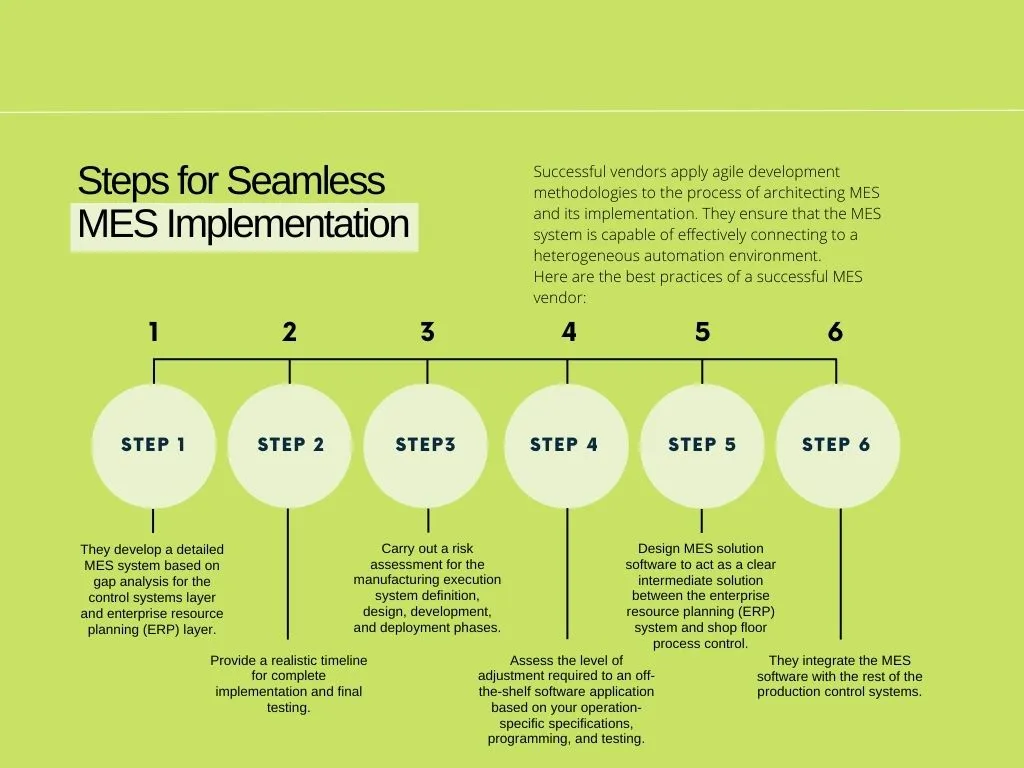

Advanced MES vendors prefer quick implementation, as less as 21 days. They take some basic yet proven steps to make the process faster. For example, they assess the hardware/automation layer during the initial project review to save the integration timeline.

Also, they go for an early-stage assessment of the state of your production equipment responsible to deliver data to the system. Besides, “Manufacturing execution systems software” “MES” is mostly cloud-based so your system gets connected with a ready-to-use highly secure server.

5- The manpower cost to be able to operate such a system is also

high and poses a deterrent.

Solution:

The vendor trains a few individuals the client company chooses as the primary operator of MES who further trains the rest of the staff. Essentially, there is no manpower cost to operate since it is cloud- based. The vendor looks after the system for its maintenance and security monitoring.

The factory owner gets a customized dashboard that makes your factory manageable through your mobile phone.

Our blog Reasons To Implement A Smart Manufacturing Integration Platform will highlight more on MES features which you should definitely read and gain knowledge.

How a Successful Vendor Achieves Seamless MES Implementation

Summary

Upgrading the existing infrastructure is not easy for any manufacturing company, especially those that belong to mediocre industry size. But modern and successful “Manufacturing execution systems software” “MES” vendors are now much more advanced to ensure smooth implementation of the system in small to medium factories.

Gradually, they are addressing the issues encountered by the factories and emerging as an effective solution for accurate and quick order processing, materials management, and personnel tracking.

*https://www.theinsightpartners.com/reports/manufacturing-execution-system-market